BQ24060的鋰離子電池充電器

鋰離子電池充電器的(de)發熱問(wen)題(ti)(ti)一直是電(dian)(dian)(dian)(dian)子(zi)工程師(shi)在(zai)進行(xing)鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)器(qi)設(she)計時的(de)難(nan)點(dian)之一,如(ru)果設(she)計不周(zhou)密,會帶(dai)來安全(quan)問(wen)題(ti)(ti)。從(cong)電(dian)(dian)(dian)(dian)量(liang)和(he)容量(liang)兩方(fang)(fang)面來講,鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)的(de)能(neng)(neng)量(liang)密度都很大(da),因此廣(guang)泛(fan)(fan)應(ying)用(yong)(yong)于便攜式設(she)備(bei),如(ru)PDA、MP3、手機、數碼相機等。由于高集成度線性電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)器(qi)簡單易用(yong)(yong)、成本低、體積小,因此廣(guang)泛(fan)(fan)應(ying)用(yong)(yong)于為(wei)單體鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)。但是,如(ru)果用(yong)(yong)不具(ju)備(bei)熱調節功(gong)能(neng)(neng)的(de)適配(pei)器(qi)給便攜式系統鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian),線性充(chong)(chong)電(dian)(dian)(dian)(dian)器(qi)的(de)散(san)(san)熱難(nan)題(ti)(ti)就會凸顯出來,難(nan)以保(bao)證在(zai)安全(quan)散(san)(san)熱范(fan)圍內工作(zuo)。這里介紹一種(zhong)基(ji)于TI公(gong)司的(de)鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)器(qi)專用(yong)(yong)芯片(pian)BQ24060、支持熱調節保(bao)護(hu)功(gong)能(neng)(neng)的(de)鋰(li)(li)(li)離(li)(li)子(zi)電(dian)(dian)(dian)(dian)池(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)器(qi)的(de)設(she)計方(fang)(fang)法。它不僅能(neng)(neng)夠(gou)使工程師(shi)完善散(san)(san)熱方(fang)(fang)面的(de)考慮(lv),同時還(huan)能(neng)(neng)極(ji)大(da)化充(chong)(chong)電(dian)(dian)(dian)(dian)率,盡可能(neng)(neng)縮短充(chong)(chong)電(dian)(dian)(dian)(dian)時間,同時具(ju)備(bei)輸(shu)入(ru)過(guo)壓(ya)保(bao)護(hu)(VOP)功(gong)能(neng)(neng)。有著較強的(de)實用(yong)(yong)性。

1 BQ24060芯片功能特點

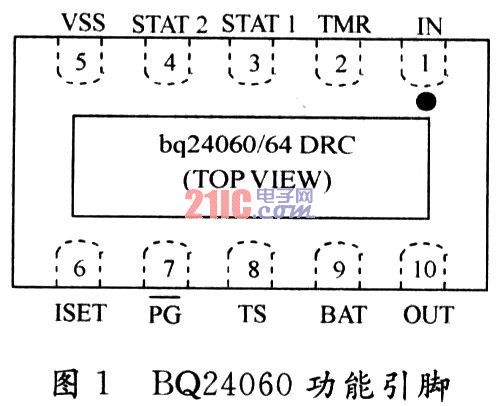

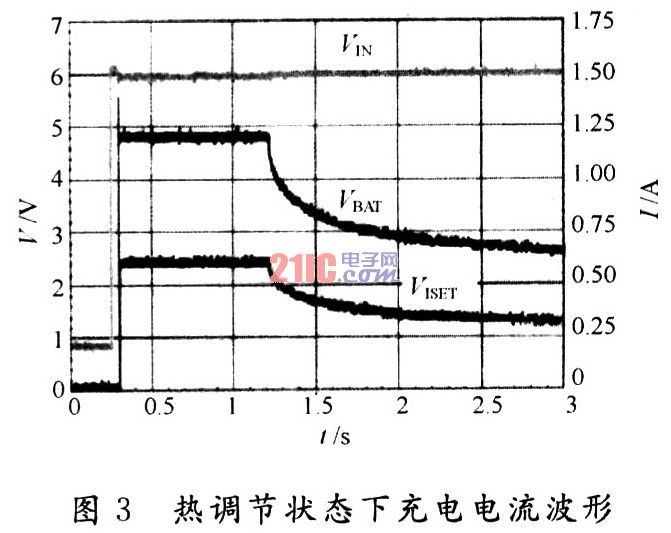

BQ24060是TI公(gong)司的(de)(de)一個高集成(cheng)的(de)(de)鋰離子(zi)(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)管理IC,其功(gong)(gong)能(neng)(neng)引(yin)腳如(ru)圖1所示(shi),表1介紹了各引(yin)腳功(gong)(gong)能(neng)(neng)。BQ24060提(ti)(ti)供能(neng)(neng)在有限空間里(li)完(wan)成(cheng)多(duo)功(gong)(gong)能(neng)(neng)的(de)(de)、安全的(de)(de)滿充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)的(de)(de)鋰離子(zi)(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)器(qi)設計,其內(nei)(nei)部集成(cheng)了1 A功(gong)(gong)率FET以及電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流傳(chuan)感器(qi),因而能(neng)(neng)夠承受高達26 V的(de)(de)輸(shu)入電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)。該產(chan)品(pin)還提(ti)(ti)供具(ju)備獨特安全與低壓(ya)降特性的(de)(de)全面充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)管理功(gong)(gong)能(neng)(neng),以延(yan)長電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池使用(yong)壽命。BQ24060可以使鋰離子(zi)(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池分三階段進行充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian):預(yu)充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式、恒流熱(re)調(diao)節充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式、精確恒壓(ya)充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)方(fang)式。充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)終止是基于一個最小電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流。內(nei)(nei)部可編程(cheng)充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)定時器(qi)為(wei)充(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)終止和(he)在熱(re)調(diao)節狀態(tai)動(dong)態(tai)調(diao)節提(ti)(ti)供安全保障(zhang)。

BQ24060充電算法縮短了充電時間,實現了總充電量的最大化,并可保護電池免遭過熱損壞或電損壞。當電池電壓降到內部閾值以下時,BQ24060會重新開始充電,如果去除外部輸入電源,那么就會進入低功耗睡眠模式。BQ24060集成了反向阻斷保護機制,以避免在沒有DC供電的情況下發生電池漏電的情況。此外,BQ24060經過配置后,還能在LDO模式下工作,這樣,即使沒有電池,系(xi)統(tong)也(ye)能完全正常工作。在終端(duan)設備制(zhi)造過程中,LDO模式的特(te)性對全面系(xi)統(tong)測(ce)試(shi)前的電路板測(ce)試(shi)也(ye)相(xiang)當有用(yong)。

BQ24060還提供(gong)過壓(ya)保護(hu)特性,在高壓(ya)情況下,該器(qi)件能(neng)(neng)夠迅速將充(chong)電器(qi)和系統與適配器(qi)相斷連,從而實現(xian)保護(hu)功能(neng)(neng)。此外(wai),即使在環境溫度較(jiao)高的(de)惡劣(lie)環境下,增強(qiang)型熱過載保護(hu)穩壓(ya)特性也能(neng)(neng)確保BQ24060長期正常工作,比如夏季在汽(qi)車中(zhong)工作,或錯誤地連接(jie)至輸入電壓(ya)較(jiao)高的(de)適配器(qi)。

2 BQ24060的關鍵技術特性

BQ24060的關鍵技術特性為:熱穩壓特性最大化充電率;計時器引腳浮動時在LDO模式下工作;通過過壓保護將最大輸入電壓設置為26 V;集成功率FET與電流傳感器,以滿足最大1 A充電應用的需求;反向漏電保護可避免電池漏電;穩壓精度在±0.5%以內;最小電流時充電終止;預充電調節具備安全計時器功能;針對LED或系統接口的狀態輸出可指示充電與故(gu)障情況,提供電源狀態良好指示;短路(lu)與熱(re)保護。

3 BQ24060芯片熱調節保護功能

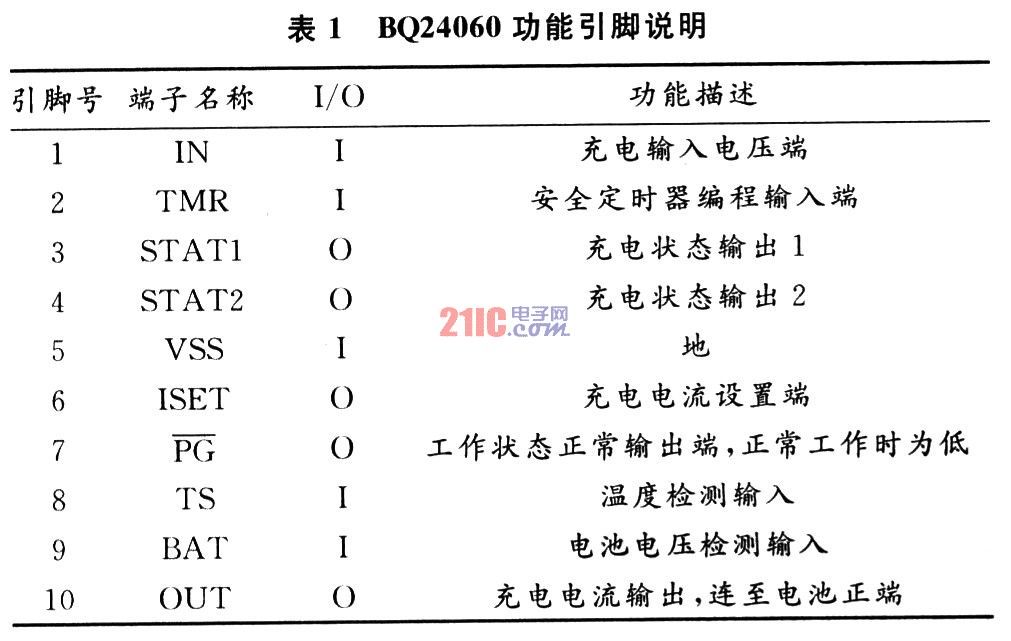

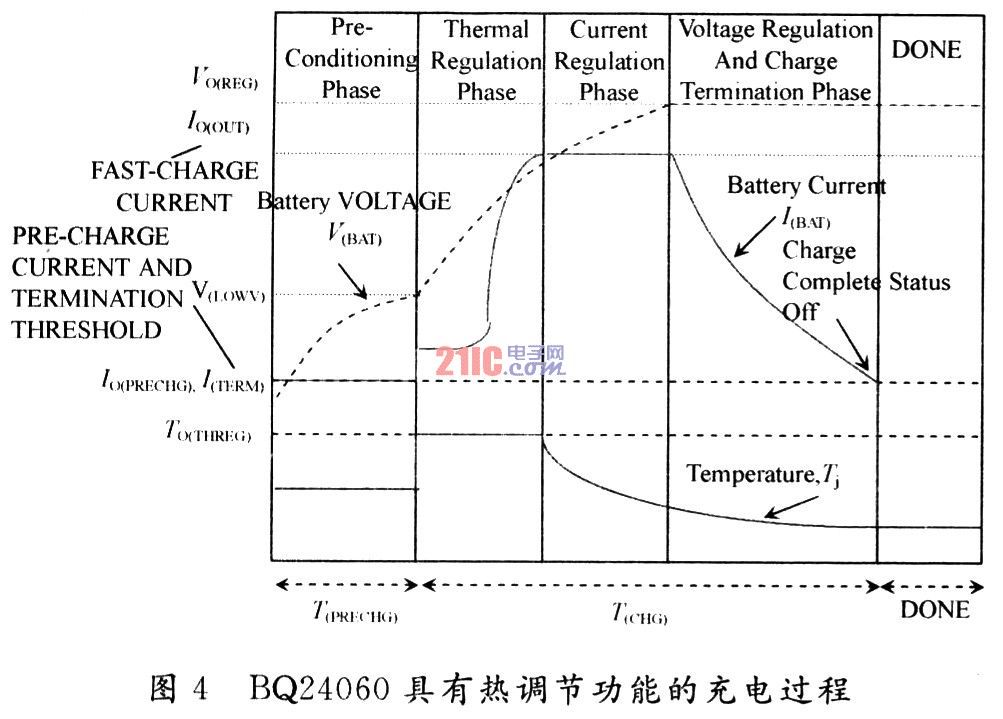

一個典型的充電過程包括三個充電階段.如圖2所示:預充電階段(Pre-Conditioning Phase)、快充恒流(CC)階段(Current Regulation Phase)、恒壓(CV)終止階段(Voltage Regulation and Charge TerminationPhase)。在預充階段,在電池電壓低于某一定值.如3.O V時,電池以較低速率充電。通常情況下,當電池電壓達到3.O V時,充電器就會進入CC階段。快充CC階段通常限制在1 C電池額定值以下。如果充電率超過1 C,那么電池使用壽命就會縮短,因為節點上積存的金屬鋰會與電解質發生反應,造成永久損失。最后,充電器會進入CV階段,這時它將保持峰值電池電壓,并在充電電流下降到預定義大小時終止充電。線性充電器的功耗計算公式:

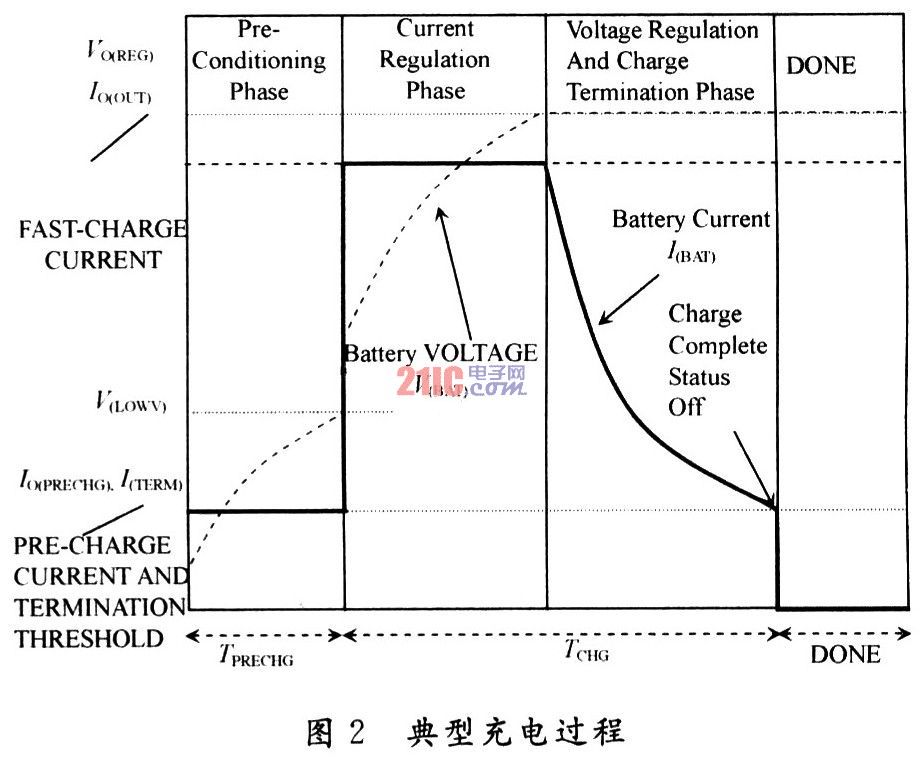

如何改進設計才能確保充電器在安全散熱范圍內正常工作,TI公司的鋰離子電池充電專用芯片BQ24060,引入了熱調節環路,可避免充電器過熱(re),給工程師設計安全的(de)充(chong)電器提供了方便。BQ24060內(nei)部芯片溫度(du)(du)達(da)到預定義的(de)溫度(du)(du)閾(yu)值后(如(ru)110℃),IC溫度(du)(du)只要(yao)進一(yi)步(bu)提升就(jiu)會(hui)讓充(chong)電電流下(xia)降,這有助于限制功(gong)耗,并為充(chong)電器提供熱(re)保護(hu)。使結溫升高(gao)到熱(re)調節的(de)極大(da)功(gong)耗取決于PCB板(ban)布局、散(san)熱(re)通孔的(de)數量以(yi)及環(huan)境溫度(du)(du)。從(cong)圖(tu)3中看(kan)出,1.2 s之(zhi)后,熱(re)環(huan)路(lu)會(hui)在2 s以(yi)內(nei)將有效充(chong)電電流從(cong)1.2 A降到600 mA。

采用(yong)BQ24060專用(yong)芯(xin)片設計(ji)的充(chong)(chong)(chong)電(dian)(dian)器,其充(chong)(chong)(chong)電(dian)(dian)過程如圖4所示,充(chong)(chong)(chong)電(dian)(dian)器從預充(chong)(chong)(chong)電(dian)(dian)階段(duan)轉向快(kuai)充(chong)(chong)(chong)模(mo)式時,充(chong)(chong)(chong)電(dian)(dian)電(dian)(dian)流IBAT受(shou)芯(xin)片結溫TJ的限制而緩慢上升,其間經歷了一個熱調節過程后(hou),充(chong)(chong)(chong)電(dian)(dian)電(dian)(dian)流IBAT達到快(kuai)充(chong)(chong)(chong)電(dian)(dian)流,進入恒(heng)流充(chong)(chong)(chong)電(dian)(dian)狀(zhuang)(zhuang)態,此(ci)后(hou)結溫開始下(xia)降,保證了充(chong)(chong)(chong)電(dian)(dian)器工作于安(an)全狀(zhuang)(zhuang)態。

如果非理想的工作條件引起IC結溫達到極限值Tj,充電循環激活內部控制回路系統將被調節,并控制其它充電控制回路,進而減小充電電流,直到IC結溫小于Tj,使IC工作于安全溫度下。

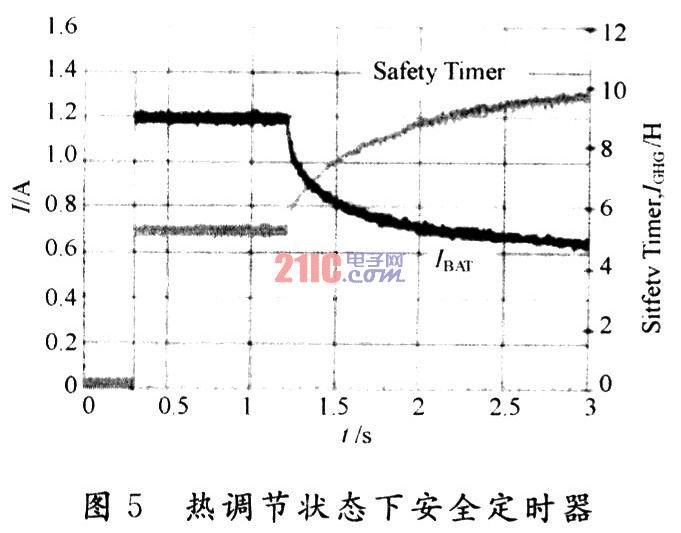

熱調節通常在快充早期階段進行,不過如果在CV模式下它仍然工作的話,充電電流就會過早達到充電終止閾值。為了避免錯誤充電終止,只要散熱調節回路在工作,電池充電終止功能就會被禁用。此外,有效充電電流降低會延長電池充電時間。如(ru)果充(chong)電(dian)安(an)全(quan)計時(shi)(shi)器(qi)有固定設置的(de)話(hua),就會過早(zao)終止充(chong)電(dian)。BQ24060采用動態安(an)全(quan)計時(shi)(shi)器(qi)控制(zhi)電(dian)路,能在(zai)熱調節階段有效(xiao)延長安(an)全(quan)時(shi)(shi)間(jian),并盡可能降低(di)安(an)全(quan)計時(shi)(shi)器(qi)的(de)故障(zhang)幾率。從圖5中(zhong)可以看出,熱調節模式下(xia)的(de)安(an)全(quan)計時(shi)(shi)器(qi)的(de)響應與有效(xiao)充(chong)電(dian)電(dian)流(liu)成反(fan)比。

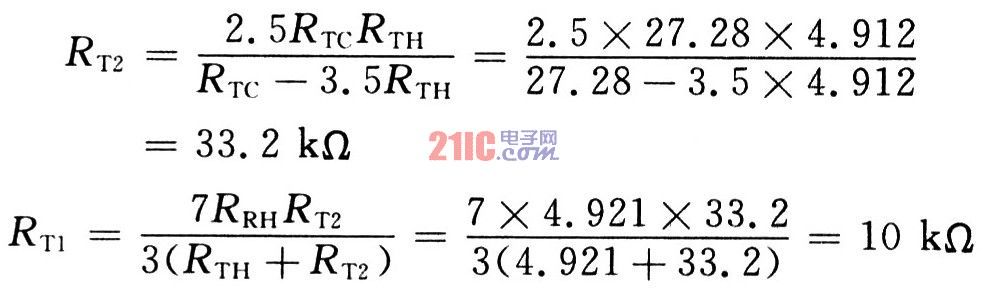

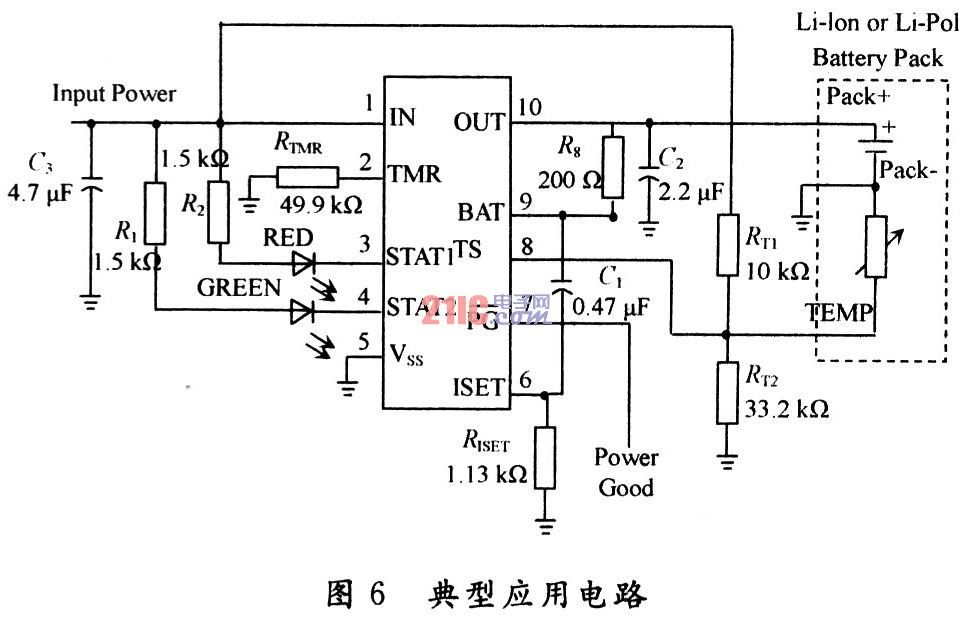

外(wai)部熱敏電阻(zu)(zu)RT1和(he)RT2可以(yi)用(yong)來設置選擇溫度(du)控制充電窗口,如圖6所示。假設RTH和(he)RTC是熱敏電阻(zu)(zu)的高(gao)低溫極限(xian)值,RT1和(he)RT2是負溫度(du)系數(shu)熱敏電阻(zu)(zu),則RT1和(he)RT2可以(yi)用(yong)如下公式(shi)計算,先計算RT2,然后將(jiang)RT2代入計算RT1:

對(dui)于某熱敏電阻,如果(guo)0℃和45℃對(dui)應的(de)阻值分別為(wei)27.28 kΩ和4.912 kΩ,代入上面兩(liang)式,得:

4.2 快充電流750 mA的設計

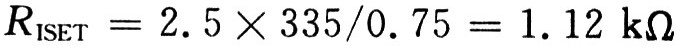

快充(chong)電流(liu)的(de)設置是通過調節BQ24060的(de)第(di)6腳(jiao)ISET端與(yu)地(di)Vss間的(de)阻抗RISET的(de)值來決定的(de),其計算(suan)公式如(ru)下:

![]()

通(tong)過查BQ24060的電特性表可(ke)得(de)VSET=2.5 V,KSET=335,當,IOUT=O.75 A時,可(ke)得(de):

因此,在BQ24060的第6腳ISET端與地間連接了一個1.13 kΩ的電阻,如圖6所示。

4.3 5h安全計時器工作時間的設計

BQ24060的安全(quan)計時(shi)器工作(zuo)時(shi)間(jian)是通(tong)過設置其第2腳TMR與地間(jian)的阻(zu)抗RTMR來決定的。其計算公式(shi)如(ru)下:

通過查BQ24060的電特性表可得KCHG=0.1 h/kΩ,則當TCHR=5h時,有RTMR=5/0.1=50 kΩ。因此,在BQ24060的第2腳(jiao)TMR與地間連接了一個(ge)49.9 kΩ的電阻,如圖6所示(shi)。

5 PCB設計

BQ24060采用有(you)(you)利于(yu)(yu)散(san)熱(re)的(de)(de)(de)MLP封(feng)裝(zhuang)形(xing)式,這(zhe)種封(feng)裝(zhuang)形(xing)式可(ke)提供一(yi)個熱(re)端(duan)面,通(tong)過(guo)(guo)直(zhi)(zhi)接焊接的(de)(de)(de)方式使(shi)IC與(yu)(yu)(yu)(yu)印刷線路板間(jian)有(you)(you)效熱(re)接觸,可(ke)靠焊接后(hou),通(tong)過(guo)(guo)熱(re)傳遞PCB就相(xiang)(xiang)當于(yu)(yu)一(yi)個蓄(xu)熱(re)裝(zhuang)置(zhi)。這(zhe)樣(yang)在(zai)設(she)計PCB時(shi)(shi)(shi)就可(ke)以(yi)(yi)合理優化設(she)計,從(cong)而最大(da)限度地(di)(di)(di)保證良(liang)好(hao)的(de)(de)(de)熱(re)傳導路徑(jing)和蓄(xu)熱(re)特(te)性(xing),從(cong)而使(shi)系統獲得極佳的(de)(de)(de)熱(re)穩定性(xing)能。本著就近原則,在(zai)電源輸(shu)入(ru)端(duan)與(yu)(yu)(yu)(yu)地(di)(di)(di)之間(jian)一(yi)般放(fang)(fang)(fang)(fang)置(zhi)一(yi)個1 μF以(yi)(yi)上的(de)(de)(de)陶瓷電容(rong)(rong)(rong),以(yi)(yi)加(jia)強高頻(pin)濾波,并有(you)(you)利于(yu)(yu)充(chong)電器(qi)短暫熱(re)插拔(ba)。該(gai)設(she)計放(fang)(fang)(fang)(fang)置(zhi)了一(yi)個4.7μF的(de)(de)(de)陶瓷電容(rong)(rong)(rong),最好(hao)通(tong)過(guo)(guo)過(guo)(guo)孔直(zhi)(zhi)接與(yu)(yu)(yu)(yu)地(di)(di)(di)層相(xiang)(xiang)連(lian)。該(gai)電容(rong)(rong)(rong)值應(ying)(ying)大(da)于(yu)(yu)電源輸(shu)出(chu)(chu)端(duan)放(fang)(fang)(fang)(fang)置(zhi)的(de)(de)(de)電容(rong)(rong)(rong)值。在(zai)電源輸(shu)出(chu)(chu)端(duan)放(fang)(fang)(fang)(fang)置(zhi)一(yi)個2.2μF的(de)(de)(de)電容(rong)(rong)(rong),同(tong)樣(yang)在(zai)布板時(shi)(shi)(shi)該(gai)電容(rong)(rong)(rong)要(yao)求就近與(yu)(yu)(yu)(yu)電源輸(shu)出(chu)(chu)端(duan)相(xiang)(xiang)連(lian),并要(yao)求短距入(ru)地(di)(di)(di),最好(hao)通(tong)過(guo)(guo)過(guo)(guo)孔直(zhi)(zhi)接與(yu)(yu)(yu)(yu)地(di)(di)(di)層相(xiang)(xiang)連(lian)。BAT和ISET端(duan)間(jian),放(fang)(fang)(fang)(fang)置(zhi)一(yi)個0.47 μF的(de)(de)(de)陶瓷電容(rong)(rong)(rong),有(you)(you)助于(yu)(yu)回路的(de)(de)(de)穩定性(xing)。在(zai)布板時(shi)(shi)(shi),所有(you)(you)小電流(liu)的(de)(de)(de)地(di)(di)(di)應(ying)(ying)與(yu)(yu)(yu)(yu)大(da)電流(liu)地(di)(di)(di)相(xiang)(xiang)互隔離,可(ke)采用單點地(di)(di)(di)技術使(shi)小信(xin)號地(di)(di)(di)與(yu)(yu)(yu)(yu)大(da)信(xin)號地(di)(di)(di)連(lian)接,在(zai)走(zou)線時(shi)(shi)(shi)要(yao)注意(yi)小信(xin)號地(di)(di)(di)與(yu)(yu)(yu)(yu)大(da)信(xin)號地(di)(di)(di)的(de)(de)(de)前后(hou)關系,避免共模干擾(rao)。

實際上,鋰離子電池充電器的要求比較高,既要實現快充,又要保證安全,其技術難點就在于電池的發熱問題。這里介紹的支持熱調節保護功能的鋰離子電池充電器的設計方法,不僅能夠使工程師完善散熱方面的考慮,同時還能極大化充電率,盡可能縮短充電時間,同時(shi)具備輸入過(guo)壓(ya)保護(VOP)功能,有著較好的實用性。