TPS5430 和MAX167 4的智能充電器

太陽能電池板的便攜式充電器是解(jie)決通信(xin)設備、田間測(ce)量儀器等移動式電(dian)(dian)(dian)(dian)(dian)(dian)(dian)子(zi)產品(pin)供電(dian)(dian)(dian)(dian)(dian)(dian)(dian)問題的最佳解(jie)決方案之一。采用TPS5430 降(jiang)壓(ya)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路和MAX167 4 升壓(ya)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路,由LM393、ICL7660 等元件構成(cheng)的切(qie)換(huan)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路為控(kong)制核心,設計具有自啟(qi)動功能(neng)的電(dian)(dian)(dian)(dian)(dian)(dian)(dian)能(neng)收集充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)器。充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)器能(neng)夠根(gen)據充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)的不同(tong)(tong),自動切(qie)換(huan)到不同(tong)(tong)的DC-DC 變換(huan)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)路,實現高效、快(kuai)速(su)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)。測(ce)試表(biao)明,當充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)源(yuan)(yuan)內(nei)(nei)阻(zu)Rs為100 Ω,充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)Es在10~20 V 范(fan)圍(wei)內(nei)(nei),充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)(dian)動勢Ec為3.6 V、內(nei)(nei)阻(zu)Rc為0.1 Ω 時,充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)Ic>58 mA,自動啟(qi)動充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)為3.6 V,電(dian)(dian)(dian)(dian)(dian)(dian)(dian)池放電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)為3 mA;而當充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)源(yuan)(yuan)內(nei)(nei)阻(zu)Rs為1 Ω,充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)Es在1.2~3.6 V 范(fan)圍(wei)內(nei)(nei)時,最大充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)流(liu)(liu)可達(da)256 mA。

太陽能的開發及利用在大力提倡發展低碳經濟的時代背景下日益受到矚目。我國光伏產業以每年30%的速度增長, 最近三年全球太陽能電池總產量平均年增長率高達49.8%以上。而通信設備、田間測量儀器等便攜式電子產品的普及使得以太陽能電池板為基礎的便攜式充電裝置倍受青睞,不受地域限制,能夠在傳統充電器無法工作的場合進行應急或可持續充電。目前,充電電池的充電技術主要有電壓負增量控制、時間控制、溫度控制、最高電壓控制技術等。假設充電電池的電壓保持恒定的條件下, 利用LM393、ICL7660等元件構成的切換電路控制, 由TPS5430 降壓電路和MAX167 4 升壓電路組成智能充電器, 由(you)可(ke)調直流電(dian)(dian)源模擬當太陽能(neng)電(dian)(dian)池板的(de)輸(shu)出(chu)電(dian)(dian)壓(ya)大(da)范圍變化(hua)時,實(shi)現(xian)充電(dian)(dian)器的(de)自動(dong)啟(qi)動(dong)并盡可(ke)能(neng)地增大(da)充電(dian)(dian)電(dian)(dian)流來實(shi)現(xian)充電(dian)(dian)效率(lv)的(de)提高。

1 理論分析與計算

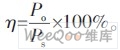

充電器的測試原理示意圖如圖1 所示。假定太陽能電池板的輸出功率有限,電動勢Es在一定范圍內緩慢變化,監測和控制電路采用間歇工作方式,以降低能耗。可充電池的電(dian)動(dong)勢Ec恒定為(wei)3.6 V,內阻Rc為(wei)0.1 Ω。

直流電源電動勢為Es,電源內阻為Rs,可充電池電動勢為Ec,可充電池內阻為Rc,充電電流為Ic,為防止電流倒灌,在可充電池兩端并聯電阻Rd。理想情況下,充電器的輸入阻抗與電源內阻匹配,此時直流電源輸出功率為

,充電器輸出功率為

,充電器輸出功率為 ,則效率為

,則效率為 。由(you)此可得,當Rs=100 Ω,Es=10 V 時,Ps=0.25 W,Ic>64 mA,η >92.16%;當Es=20 V 時,Ps=1 W,Ic>160 mA,η>57.6%。為(wei)了盡可能提高高電(dian)(dian)壓時的(de)(de)充電(dian)(dian)效(xiao)率,除選用TPS5430 構成降(jiang)壓電(dian)(dian)路外,應盡量降(jiang)低切(qie)換電(dian)(dian)路的(de)(de)開(kai)關頻(pin)率。電(dian)(dian)路中主要(yao)功耗元件是(shi)(shi)功率場效(xiao)應管(FET),在低頻(pin)情況下,功率FET 主要(yao)是(shi)(shi)傳導損耗,在高頻(pin)情況下,傳導損耗維持不變,同頻(pin)率有關的(de)(de)損耗會(hui)增大。較(jiao)高或較(jiao)低的(de)(de)開(kai)關頻(pin)率均會(hui)使效(xiao)率降(jiang)低,綜(zong)合(he)考慮各(ge)因素并結合(he)試驗(yan),測(ce)得開(kai)關頻(pin)率為(wei)500 kHz 時效(xiao)率為(wei)94.35%。

。由(you)此可得,當Rs=100 Ω,Es=10 V 時,Ps=0.25 W,Ic>64 mA,η >92.16%;當Es=20 V 時,Ps=1 W,Ic>160 mA,η>57.6%。為(wei)了盡可能提高高電(dian)(dian)壓時的(de)(de)充電(dian)(dian)效(xiao)率,除選用TPS5430 構成降(jiang)壓電(dian)(dian)路外,應盡量降(jiang)低切(qie)換電(dian)(dian)路的(de)(de)開(kai)關頻(pin)率。電(dian)(dian)路中主要(yao)功耗元件是(shi)(shi)功率場效(xiao)應管(FET),在低頻(pin)情況下,功率FET 主要(yao)是(shi)(shi)傳導損耗,在高頻(pin)情況下,傳導損耗維持不變,同頻(pin)率有關的(de)(de)損耗會(hui)增大。較(jiao)高或較(jiao)低的(de)(de)開(kai)關頻(pin)率均會(hui)使效(xiao)率降(jiang)低,綜(zong)合(he)考慮各(ge)因素并結合(he)試驗(yan),測(ce)得開(kai)關頻(pin)率為(wei)500 kHz 時效(xiao)率為(wei)94.35%。

2 硬件電路設計

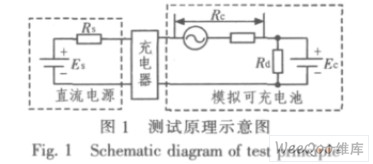

充電器硬件電路組成框圖如圖2 所示。充電器由切換電路自動判斷直流電源輸入電壓, 選擇升壓或降壓電路,實現在工作電壓范圍內自動切換, 模擬對充電電池的充電效果。

2.1 切換電路設計

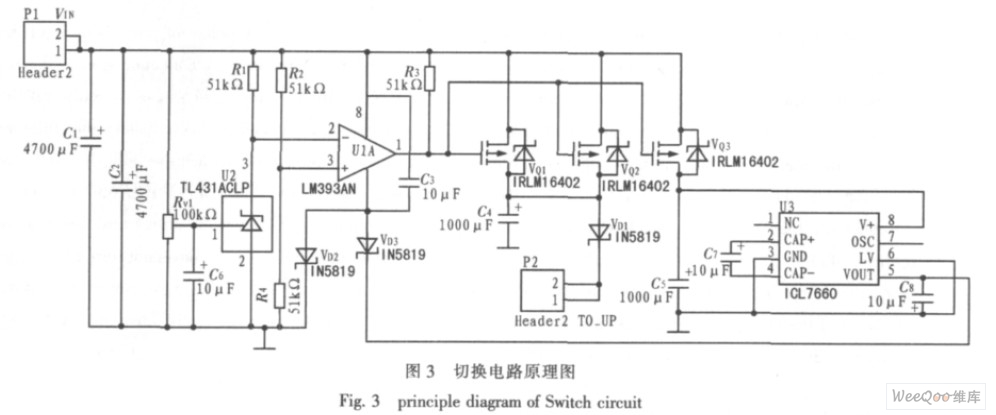

切換電路用于切換充電器升壓(ya)(ya)(ya)(ya)(ya)(ya)工作(zuo)(zuo)(zuo)和降(jiang)壓(ya)(ya)(ya)(ya)(ya)(ya)工作(zuo)(zuo)(zuo)兩種(zhong)模式。設定切換的閾(yu)值(zhi)電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)為3.6 V,閾(yu)值(zhi)電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)由可調電(dian)阻設定并可調。充電(dian)電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)超過閾(yu)值(zhi)電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)時降(jiang)壓(ya)(ya)(ya)(ya)(ya)(ya)電(dian)路(lu)工作(zuo)(zuo)(zuo),低于閾(yu)值(zhi)電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)時升壓(ya)(ya)(ya)(ya)(ya)(ya)電(dian)路(lu)工作(zuo)(zuo)(zuo)。切換電(dian)路(lu)由場效(xiao)應管、電(dian)壓(ya)(ya)(ya)(ya)(ya)(ya)比較器等(deng)分立(li)元(yuan)件構成,原理圖(tu)如圖(tu)3 所(suo)示。

圖3 中, 輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端(duan)VIN (P1) 接充電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)源(yuan), 輸(shu)(shu)(shu)(shu)出端(duan)P2 接MAX167 4升(sheng)(sheng)壓(ya)(ya)(ya)(ya)電(dian)(dian)(dian)(dian)(dian)路(lu)的輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端(duan),肖特基二極管VD1用(yong)于防止(zhi)電(dian)(dian)(dian)(dian)(dian)流倒灌。穩壓(ya)(ya)(ya)(ya)器(qi)TL431 為電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)比較器(qi)LM393 的負輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端(duan)提供參考(kao)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)。輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端(duan)VIN(P1)通過濾(lv)波(bo)后接入(ru)(ru)(ru)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)比較器(qi)LM393 的正輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)端(duan)。調節R_ad可調電(dian)(dian)(dian)(dian)(dian)阻(zu),使輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)小(xiao)于3.6 V 時(shi)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)比較器(qi)LM393 輸(shu)(shu)(shu)(shu)出負電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya),P 溝(gou)道(dao)MOS 管IRLM16402VQ1、VQ2和VQ3導(dao)通,VQ1,VQ2的漏極連接升(sheng)(sheng)壓(ya)(ya)(ya)(ya)電(dian)(dian)(dian)(dian)(dian)路(lu), 使切換電(dian)(dian)(dian)(dian)(dian)路(lu)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)、輸(shu)(shu)(shu)(shu)出端(duan)短接,使充電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)接至升(sheng)(sheng)壓(ya)(ya)(ya)(ya)電(dian)(dian)(dian)(dian)(dian)路(lu)。當(dang)輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)大于3.6 V 時(shi),輸(shu)(shu)(shu)(shu)出高(gao)電(dian)(dian)(dian)(dian)(dian)平,VQ1、VQ2和VQ3截止(zhi),此(ci)時(shi)MAX167 4升(sheng)(sheng)壓(ya)(ya)(ya)(ya)電(dian)(dian)(dian)(dian)(dian)路(lu)無輸(shu)(shu)(shu)(shu)入(ru)(ru)(ru)。VD2、VD3的作(zuo)用(yong)是當(dang)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)大于3.6 V 時(shi),LM393的負電(dian)(dian)(dian)(dian)(dian)源(yuan)端(duan)接地; 當(dang)電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)小(xiao)于5.5 V 時(shi),LM393 負電(dian)(dian)(dian)(dian)(dian)源(yuan)通過VQ3接ICL7660 的負電(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)(ya)(ya)輸(shu)(shu)(shu)(shu)出引腳(jiao)。

2.2 升壓/降壓電路設計

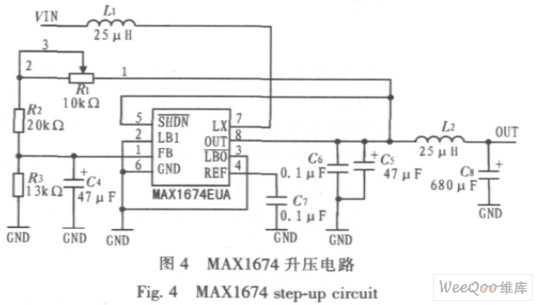

升(sheng)(sheng)(sheng)壓電路(lu)主要由升(sheng)(sheng)(sheng)壓式DC-DC 電源轉換器MAX167 4組成,升(sheng)(sheng)(sheng)壓后輸出4 V 直接(jie)對電池進(jin)行充電。MAX167 4升(sheng)(sheng)(sheng)壓電路(lu)如(ru)圖(tu)4 所示。

圖4 中, 升壓芯片的儲能電感L1接MAX167 4的LX 引腳,電阻R1、R2和R3構成反饋網絡,將輸出電壓反饋至FB 引腳,芯片內部保持輸出電壓恒定。選取25 μH 電感和680 μF電容組成一階低通濾波器,截止頻率 ,以削弱紋(wen)波對輸出電壓的影響。

,以削弱紋(wen)波對輸出電壓的影響。

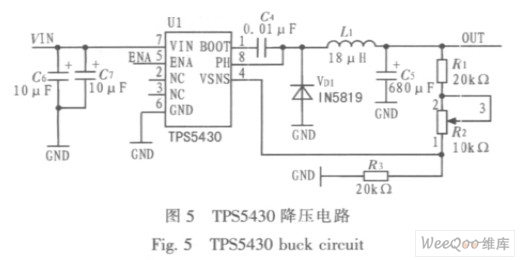

降(jiang)壓(ya)電(dian)路(lu)主(zhu)要由降(jiang)壓(ya)DC-DC 轉換器TPS5430 組成,降(jiang)壓(ya)后直接對電(dian)池進行(xing)充電(dian)。TPS5430 降(jiang)壓(ya)電(dian)路(lu)如圖(tu)5 所示。

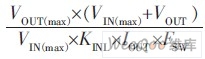

經測試,綜合考慮效率因素,選定開關頻率為500 kHz,輸入端的電容C6和C7為旁路電容和降壓濾波電容, 由于轉換器中開關在導通瞬間需要較大電流,通過旁路電容吸收瞬間大電流和濾除高頻噪聲信號使芯片保持穩定工作。電路輸出功率越大,工作頻率越低,對應的電容值也應越大。選取等效串聯電阻阻值低,容值為10 μF 的電解電容。根據芯片數據資料, 輸出端電感L1的取值按公式

計算, 可得(de)所需的電(dian)感值(zhi)是(shi)15.8 μH,選取(qu)內徑(jing)30 mm 的鐵(tie)硅鋁磁芯自(zi)行(xing)繞(rao)制的電(dian)感值(zhi)為18 μH,以保證(zheng)在(zai)額定的工作(zuo)狀況下不會出(chu)(chu)(chu)現磁飽和。電(dian)阻R1、R2和R3構成(cheng)反(fan)饋網絡, 將輸(shu)出(chu)(chu)(chu)電(dian)壓反(fan)饋到芯片的VSNS 引腳(jiao),該芯片自(zi)動調(diao)節(jie)輸(shu)出(chu)(chu)(chu)電(dian)壓,保證(zheng)充電(dian)器輸(shu)出(chu)(chu)(chu)端(duan)輸(shu)出(chu)(chu)(chu)電(dian)壓恒定。

計算, 可得(de)所需的電(dian)感值(zhi)是(shi)15.8 μH,選取(qu)內徑(jing)30 mm 的鐵(tie)硅鋁磁芯自(zi)行(xing)繞(rao)制的電(dian)感值(zhi)為18 μH,以保證(zheng)在(zai)額定的工作(zuo)狀況下不會出(chu)(chu)(chu)現磁飽和。電(dian)阻R1、R2和R3構成(cheng)反(fan)饋網絡, 將輸(shu)出(chu)(chu)(chu)電(dian)壓反(fan)饋到芯片的VSNS 引腳(jiao),該芯片自(zi)動調(diao)節(jie)輸(shu)出(chu)(chu)(chu)電(dian)壓,保證(zheng)充電(dian)器輸(shu)出(chu)(chu)(chu)端(duan)輸(shu)出(chu)(chu)(chu)電(dian)壓恒定。

3 試驗結果及分析

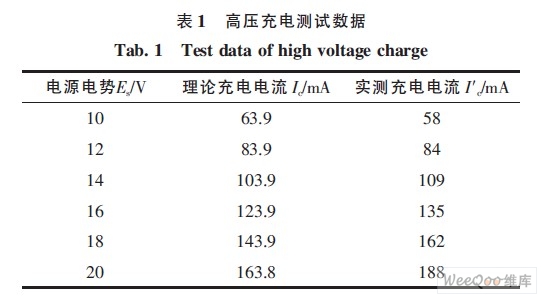

1)電(dian)源內阻Rs=100 Ω,調(diao)整(zheng)Es的大小,使(shi)其在10~20 V范(fan)圍內變(bian)化(hua),記錄數據如表(biao)1 所示(shi)。

由表1 可(ke)見,在Es為10 V 時,實(shi)測充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)與理論(lun)值存在5.9 mA 的偏差(cha),充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)低、充(chong)電(dian)(dian)(dian)(dian)器的轉換效率(lv)不高可(ke)能與芯片的轉換效率(lv)和輸(shu)(shu)入電(dian)(dian)(dian)(dian)壓(ya)有(you)關(guan),由TPS5430 的數(shu)據資料可(ke)知,在輸(shu)(shu)入電(dian)(dian)(dian)(dian)壓(ya)為10 V 左(zuo)右,輸(shu)(shu)出電(dian)(dian)(dian)(dian)流(liu)約(yue)為60 mA 時,其工(gong)作效率(lv)約(yue)為92%。而在12~20 V 范圍內,實(shi)測充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)大(da)于理論(lun)計算(suan)充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)值。

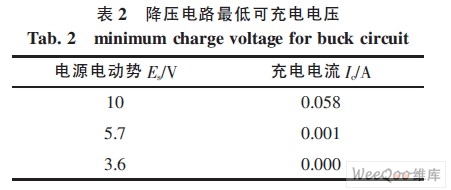

2)逐漸降低(di)Es,直到充電電流Ic略大(da)于0 時,記錄(lu)對應的電源電壓(ya)(ya)Es,該電壓(ya)(ya)即為最(zui)低(di)可充電電壓(ya)(ya)。為保證準確性,對多個不同的電源電壓(ya)(ya)值進行測試,選(xuan)取最(zui)優3 組數據記錄(lu)如表2 所示。

由表2 可見(jian),當Es下(xia)降到3.6 V 時(shi),充(chong)(chong)電電流(liu)為0,充(chong)(chong)電器不能(neng)再(zai)對電池進行(xing)充(chong)(chong)電,故最(zui)低可充(chong)(chong)電電壓為3.6 V。

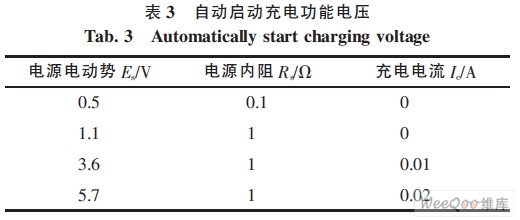

3)從(cong)0 開始(shi)逐漸(jian)升(sheng)高(gao)Es,Rs為(wei)0.1 Ω;當Es升(sheng)高(gao)到(dao)高(gao)于1.1 V 時,更(geng)換(huan)Rs為(wei)1 Ω。然后繼續升(sheng)高(gao)Es,直到(dao)充(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流略大于0,記錄(lu)此時的電(dian)(dian)(dian)源(yuan)電(dian)(dian)(dian)壓(ya)值,該電(dian)(dian)(dian)壓(ya)即(ji)為(wei)自動啟動充(chong)電(dian)(dian)(dian)功能的啟動電(dian)(dian)(dian)壓(ya)。為(wei)保證準確性,對多(duo)個(ge)不(bu)同的電(dian)(dian)(dian)源(yuan)電(dian)(dian)(dian)壓(ya)值進行(xing)測試,選取最優4 組數據記錄(lu)如表3 所示(shi)。

由表(biao)3 可見,當Es小于3.6 V 時,充(chong)電(dian)電(dian)流(liu)持續(xu)為0,一旦Es上升(sheng)到(dao)3.6 V 后,充(chong)電(dian)電(dian)流(liu)由0 開始增(zeng)加,即自動啟動充(chong)電(dian)電(dian)壓為3.6 V。

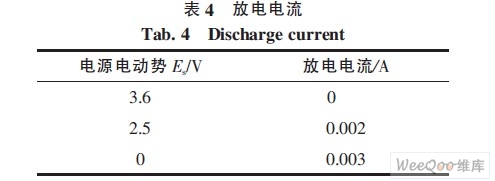

4)Es降低到(dao)不能向(xiang)電(dian)(dian)池充(chong)電(dian)(dian),最低至(zhi)0 時,檢測(ce)放電(dian)(dian)電(dian)(dian)流。為保證準確性(xing),對多個不同的電(dian)(dian)源電(dian)(dian)壓值進行測(ce)試,選取最優3 組(zu)數據(ju)記錄如表4 所示(shi)。

由表4 可知, 當(dang)電(dian)源電(dian)動勢下(xia)降到最低(di)可充電(dian)電(dian)壓時(shi),電(dian)池開(kai)始放電(dian),放電(dian)電(dian)流(liu)為(wei)3 mA。考慮到放電(dian)電(dian)流(liu)受倒灌電(dian)阻Rd影響(xiang),改變Rd的大小可改變放電(dian)電(dian)流(liu)。試(shi)驗表明,Rd=15 Ω 時(shi)放電(dian)電(dian)流(liu)最小。

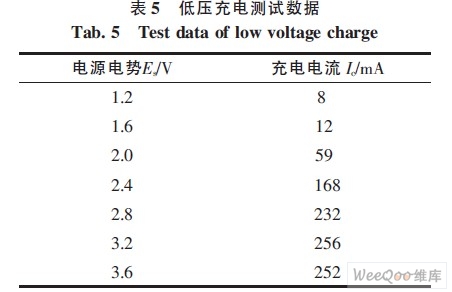

5)接(jie)上電(dian)源內阻Rs=1 Ω,調(diao)整(zheng)Es,使其在1.2~3.6 V 范圍(wei)內變化。數(shu)據記(ji)錄如表(biao)5 所(suo)示。

由表5 可見,隨(sui)著(zhu)電(dian)(dian)(dian)(dian)(dian)源(yuan)電(dian)(dian)(dian)(dian)(dian)勢(shi)的(de)增(zeng)加(jia),充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流(liu)也隨(sui)著(zhu)增(zeng)加(jia),直到當Es達到3.2 V 時,充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流(liu)不(bu)(bu)再跟隨(sui)電(dian)(dian)(dian)(dian)(dian)源(yuan)電(dian)(dian)(dian)(dian)(dian)勢(shi)變(bian)(bian)化。當電(dian)(dian)(dian)(dian)(dian)源(yuan)電(dian)(dian)(dian)(dian)(dian)勢(shi)為3.2 V 時,充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流(liu)最(zui)大,為256 mA。導致充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流(liu)突(tu)(tu)變(bian)(bian)的(de)原因是升(sheng)壓(ya)器(qi)件MAX1* 在不(bu)(bu)同(tong)輸(shu)入電(dian)(dian)(dian)(dian)(dian)壓(ya)下(xia)(xia)轉(zhuan)換效(xiao)率(lv)(lv)不(bu)(bu)同(tong)。由于MAX1* 在超過3 V 電(dian)(dian)(dian)(dian)(dian)壓(ya)下(xia)(xia)工作時轉(zhuan)換效(xiao)率(lv)(lv)低(di),所以充(chong)電(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)流(liu)出(chu)現(xian)非線性的(de)突(tu)(tu)變(bian)(bian)。

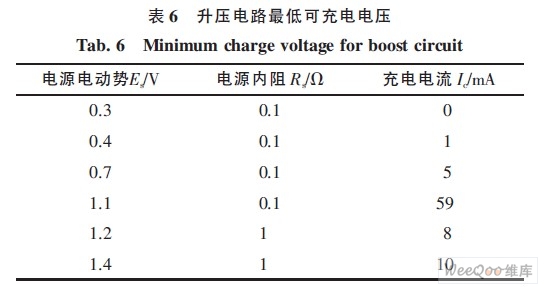

6)當Es≥1.1 V 時(shi),取(qu)(qu)Rs =1 Ω;當Es<1.1 V 時(shi),取(qu)(qu)Rs=0.1 Ω。測量向電池充電的Es,記錄數據如表6 所(suo)示。

由表6 可知,逐漸降低電源電勢Es時,充電電流也隨著下降。當Es到達0.4 V 時輸出電壓已經在0 V 附近變化,因此能向電池充電的最低Es為(wei)0.4 V。

4 結論

本設計以切換電路為控制核心,控制升壓型電路和降壓型電路對電池進行充電。該充電器輸出電壓能夠恒定在4 V,自動啟動充電功能的Es為3.6 V,Es降低到不能向電池充電時,電池放電電流為3 mA,電路適合由輸出電壓波動較大的太陽能電池板供電的便攜式充電器,且充電效率高于傳統的充電器。