LLC的大功率智能充電器

充電器與人們的日常生活密切相關,充電器充電性能的好壞與被充電池的使用壽命、充電效率等息息相關。 由于外界溫度變化,電網電壓波動,因而大大降低了充電器充電性能的穩定性,這就需要有一種能自我調節的系統,遇到外界的干擾能實時做出回應,保證充電的(de)(de)(de)(de)穩定性(xing),不損壞被(bei)充電(dian)(dian)的(de)(de)(de)(de)電(dian)(dian)池。 智能控(kong)(kong)制(zhi)在(zai)(zai)此能提供一(yi)(yi)種很(hen)好的(de)(de)(de)(de)解決方案。電(dian)(dian)源(yuan)行業已經開始在(zai)(zai)其(qi)產品中(zhong)運用智能控(kong)(kong)制(zhi),通(tong)過(guo)(guo)單(dan)片機的(de)(de)(de)(de)編(bian)程(cheng)對過(guo)(guo)壓、過(guo)(guo)流情(qing)況做出判斷,為(wei)電(dian)(dian)池提供保護。 LLC 諧(xie)振(zhen)(zhen)變換(huan)器(qi)(qi)在(zai)(zai)充電(dian)(dian)器(qi)(qi)的(de)(de)(de)(de)運用也是(shi)越來越多,LLC 諧(xie)振(zhen)(zhen)變換(huan)器(qi)(qi)的(de)(de)(de)(de)拓撲(pu)本身(shen)具有(you)一(yi)(yi)些優越的(de)(de)(de)(de)性(xing)能,可(ke)以實現原邊開關管(guan)在(zai)(zai)全負載下(xia)的(de)(de)(de)(de)零電(dian)(dian)壓軟開關( ZVS ( Zero VoltageSwitch) ) ,副邊整流二極(ji)管(guan)電(dian)(dian)壓應力低,因(yin)此高輸出電(dian)(dian)壓的(de)(de)(de)(de)情(qing)況下(xia)可(ke)以實現較高的(de)(de)(de)(de)效率等。 這使得LLC 諧(xie)振(zhen)(zhen)變換(huan)器(qi)(qi)特(te)別適合(he)高輸出電(dian)(dian)壓的(de)(de)(de)(de)應用場合(he)。 今后電(dian)(dian)源(yuan)的(de)(de)(de)(de)發(fa)展方向是(shi)用單(dan)片機來完(wan)成(cheng)所有(you)功(gong)能,包括:脈寬調(diao)控(kong)(kong)、反饋、過(guo)(guo)壓過(guo)(guo)流保護等等。

下面介紹的就是一款應比亞迪公司(B YD) 的要求,設計出的一種基于單片機的智能充電器。 該充電器對充電(dian)過程進行智能控制,系統中的管(guan)理電(dian)路還具(ju)有保護功能,可防止電(dian)池(chi)的過充和過放(fang)對電(dian)池(chi)造成(cheng)損壞。

1 LLC 諧振變換器(qi)

本充電器設計中要考慮整流濾波、能量轉換,電路保護、軟件設計等。 而LLC 諧振變換器是能量轉換中最重要的部分,關系到充電器性(xing)能的好壞。 下(xia)面著重介紹其(qi)基本結構、數學模型及時(shi)序分(fen)析。

1. 1 LLC 諧振(zhen)變換(huan)器的基(ji)本結構

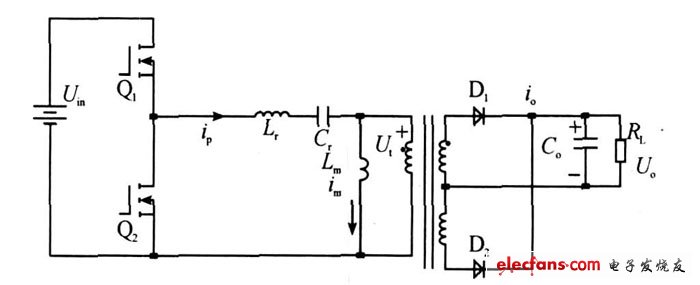

圖1 所示為(wei)LLC 諧(xie)(xie)(xie)振(zhen)(zhen)(zhen)變換器的原理圖。 串(chuan)聯諧(xie)(xie)(xie)振(zhen)(zhen)(zhen)電感(gan)(gan)Lr 、串(chuan)聯諧(xie)(xie)(xie)振(zhen)(zhen)(zhen)電容Cr 和(he)并(bing)聯諧(xie)(xie)(xie)振(zhen)(zhen)(zhen)電感(gan)(gan)Lm ,構(gou)成LLC 諧(xie)(xie)(xie)振(zhen)(zhen)(zhen)網絡, Cr 也(ye)起到(dao)隔直(zhi)作用[3 ] 。 在(zai)變壓器次級,整流二極管直(zhi)接連接到(dao)輸出電容Co上。

圖1 LLC 諧(xie)振變(bian)換器(qi)的原理(li)圖

當發生諧振時,LC 的本征諧振頻率為:

![]()

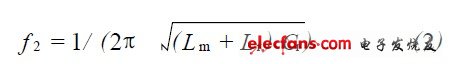

當(dang)Lr , Cr 和(he)Lm發生諧振時,LLC 本征諧振頻率為:

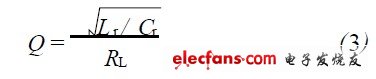

由式(1) 、(2) 可(ke)知f1 》 f2 ,當負載RL 變化時(shi),可(ke)以(yi)調節開關(guan)(Q1 、Q2 ) 頻率在f1 和f2 間(jian)變化,使(shi)品質因(yin)數達到最大。 利用這種(zhong)特性,可(ke)以(yi)方便地(di)實現脈沖頻率模式PFM( Pul se Frequency Model) ,品質因(yin)數表示(shi)如下:

LLC 諧振網絡需要兩個磁性元件(jian)Lr 和Lm。

然而,考慮到高頻變壓器實際結構,可以把磁性元件Lr 和Lm 集成在一個變壓器內,利用變壓器的漏感作為Lr , 利用變壓器的磁化電感作為Lm , 這樣一來,可以大大減少磁性元件數目。 在設計時,只要重點設計變壓器的漏感與變壓器磁化電感即可。 因此, 為增加漏感, 需要在變壓器中加入適當的氣隙,并且控制變壓器原、副邊的繞線方式可以提高品質因素。

1. 2 LLC 的數學模型分析

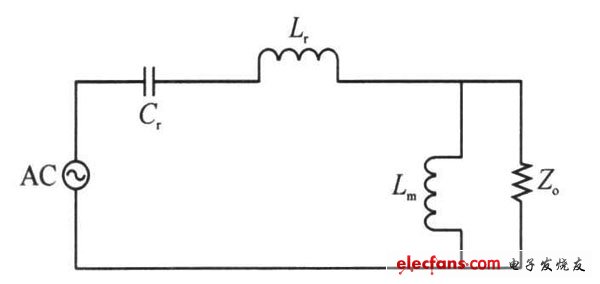

通過上述分析(xi),由圖1 的LLC 諧振變(bian)換器的原(yuan)理圖得其LLC 等效模型如圖2 所(suo)示。

圖(tu)2 LLC 原理圖(tu)的等效模型圖(tu)

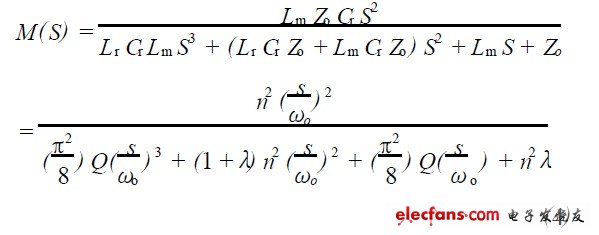

電(dian)壓(ya)傳(chuan)遞函數為:

其中:

Q 為品質因數。

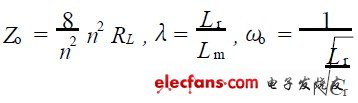

利用(yong)MA TIAB 對該模型進(jin)行(xing)仿真(zhen),可(ke)以初步分析出其工作特性如圖3 所(suo)示。 其中f s 為(wei)啟動頻率(lv)(lv)( Start Frequency) f r 為(wei)諧振頻率(lv)(lv)( ResonantFrequency)。

圖3 LLC 諧振工作特性(xing)。

從圖3 中可(ke)以看到,在(zai)整個(ge)頻率圍(wei)內,既有降壓的工(gong)作(zuo)(zuo)(zuo)區(qu)域(M 《 1) ,也有升壓的工(gong)作(zuo)(zuo)(zuo)區(qu)域( M 》1) ,此LLC 諧(xie)振(zhen)有著較大的應用范圍(wei)。 在(zai)輕負(fu)載時(shi),工(gong)作(zuo)(zuo)(zuo)頻率逐(zhu)漸(jian)升高, 工(gong)作(zuo)(zuo)(zuo)在(zai)降壓區(qu)域內; 而在(zai)重負(fu)載時(shi), 工(gong)作(zuo)(zuo)(zuo)頻率逐(zhu)漸(jian)降低, 工(gong)作(zuo)(zuo)(zuo)在(zai)升壓區(qu)域內。 由圖3 可(ke)知, 串(chuan)聯諧(xie)振(zhen)的工(gong)作(zuo)(zuo)(zuo)區(qu)域應該為f s / f r 》 1 ,才能工(gong)作(zuo)(zuo)(zuo)在(zai)ZVS 的狀(zhuang)態。 在(zai)不同(tong)負(fu)載下,為獲得ZVS 的工(gong)作(zuo)(zuo)(zuo)條件, 只(zhi)要使之工(gong)作(zuo)(zuo)(zuo)在(zai)f s / f r 》 1的右側即可(ke)。 而LLC 諧(xie)振(zhen)不僅僅局限于f s / f r 》 1 的區(qu)域, 在(zai)某(mou)些負(fu)載下可(ke)以工(gong)作(zuo)(zuo)(zuo)在(zai)f s / f r 《 1區(qu)域。 同(tong)樣(yang)可(ke)以獲得零電壓轉換的工(gong)作(zuo)(zuo)(zuo)狀(zhuang)況。 并且與(yu)串(chuan)聯諧(xie)振(zhen)相(xiang)比,在(zai)不同(tong)負(fu)載時(shi)的頻率變化范圍(wei)更小。

1. 3 LLC 諧振變換器的時序分析

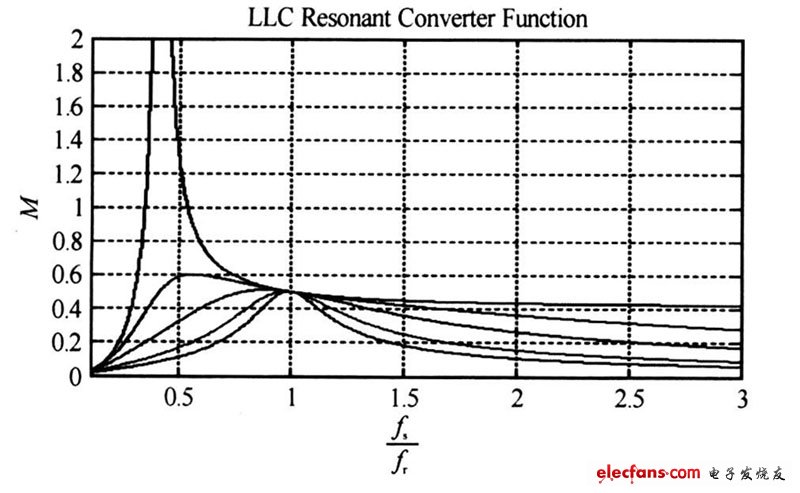

LLC 諧振(zhen)變換(huan)器由兩個主(zhu)開關管(guan)Q1 和Q2 構成,其(qi)驅(qu)動信號是(shi)占(zhan)空比固(gu)定為0. 5 的互補驅(qu)動信號。 為了(le)保證原(yuan)邊功率MOS 管(guan)的ZVS , 副邊二(er)極管(guan)的ZCS(Zero Current Switch) 都可(ke)以實(shi)現,工作頻率在(zai)f 2 《 f ≤f 1 時, 其(qi)工作波形圖如圖4 所示。 從圖中可(ke)以看出LLC 變換(huan)器工作在(zai)半(ban)個周期內可(ke)以分為三個工作模式(shi)。

模式1 (t0 - t1):兩個(ge)開關管(Q1 、Q2 ) 都截止,Q1 的(de)反向二級管導通續流, Lr 上的(de)電流逐漸(jian)減(jian)小,變壓器產生感生電流,向負(fu)載(zai)供電。 反向二極管的(de)導通將Q1兩端的(de)電壓鉗位(wei)在(zai)零。

模式(shi)2 (t1 - t2):Lr 上的電流在t1 時(shi)刻(ke)減(jian)小到(dao)(dao)零,Q1 在此時(shi)刻(ke)導通, Lr 上的電流反向增(zeng)大, 達到(dao)(dao)峰值后(hou)減(jian)小。 Lm 上的電流先減(jian)小,然后(hou)反向增(zeng)加(jia)。

可以看出,t1 時刻由(you)于Q1 的反向二(er)極管的鉗位作用(yong),Q1 的導(dao)通電壓為零。 此階(jie)段只有Lr 和Cr 進行諧振。

圖(tu)(tu)4 工(gong)作時序(xu)波形圖(tu)(tu)

模式3 (t2 - t3):Lm 上的(de)電(dian)(dian)流(liu)(liu)在t2 時(shi)刻與Lr上的(de)電(dian)(dian)流(liu)(liu)相等,此(ci)時(shi)流(liu)(liu)過變壓器的(de)電(dian)(dian)流(liu)(liu)為零,負載與變壓器被(bei)隔(ge)離開。Q1 在此(ci)時(shi)刻關斷,Q2的(de)反向二(er)極管(guan)導通續流(liu)(liu)。 此(ci)階(jie)段Lm 也加入到諧振(zhen)部(bu)分, 與Lr 和Cr 串聯(lian)組成諧振(zhen)回路。

在(zai)下半(ban)個周(zhou)期中, 電(dian)(dian)(dian)(dian)路(lu)的工(gong)作(zuo)與上(shang)半(ban)個周(zhou)期剛(gang)剛(gang)相似,只是方向相反(fan)。整(zheng)個周(zhou)期的電(dian)(dian)(dian)(dian)路(lu)工(gong)作(zuo)波形:在(zai)上(shang)半(ban)個周(zhou)期中,開(kai)關(guan)管Q1 為零電(dian)(dian)(dian)(dian)壓(ya)(ya)導通, 而(er)(er)Q1 在(zai)t3 時刻(ke)的關(guan)斷電(dian)(dian)(dian)(dian)流im 很小; 在(zai)下半(ban)個周(zhou)期中,開(kai)關(guan)管Q2 為零電(dian)(dian)(dian)(dian)壓(ya)(ya)導通,而(er)(er)Q2 在(zai)t6 時刻(ke)的關(guan)斷電(dian)(dian)(dian)(dian)流im 很小,所(suo)以Q1 、Q2 工(gong)作(zuo)時的開(kai)關(guan)損耗(hao)很小。

2 充電(dian)器(qi)硬件(jian)設計

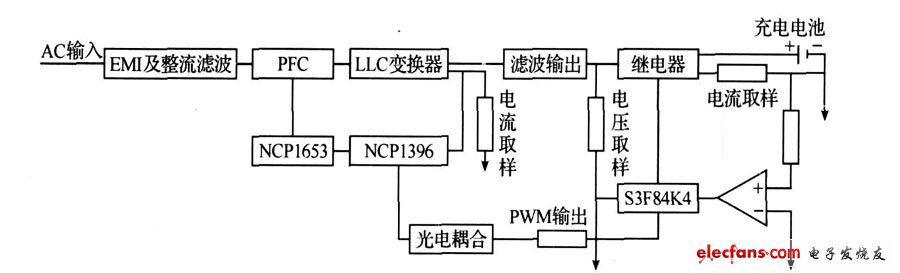

經(jing)過(guo)上面的分(fen)析(xi),設計中采用電(dian)(dian)流、電(dian)(dian)壓負(fu)反(fan)饋的方法來達到恒流、恒壓充電(dian)(dian)的目的,充電(dian)(dian)器硬件原理框圖如圖5 所(suo)示。

圖(tu)5 充電器的硬件原理框圖(tu)

交流(liu)電經過(guo)濾波整(zheng)流(liu)后,流(liu)向NCP1653,由其提供PFC(Power Factor Correction) 操作(zuo),NCP1653是(shi)一(yi)(yi)款(kuan)連續導通(tong)型(CCM) 的(de)功(gong)率因數校(xiao)正( PFC) 升壓(ya)式的(de)上升控(kong)制電路(lu)(lu), 它的(de)外圍元器件(jian)數量很少(shao),有(you)效(xiao)地(di)減(jian)少(shao)了(le)(le)升壓(ya)電感(gan)的(de)體積, 減(jian)小(xiao)了(le)(le)功(gong)率MOS管的(de)電流(liu)應(ying)力,從而降低了(le)(le)成本,且極大地(di)簡化了(le)(le)CCM 型的(de)PFC 的(de)操作(zuo),它還集成了(le)(le)高可靠的(de)保護(hu)功(gong)能。 NCP1396 電路(lu)(lu)為整(zheng)個(ge)硬件(jian)電路(lu)(lu)提供保護(hu)(包括(kuo)有(you)反(fan)饋環路(lu)(lu)失效(xiao)偵測、快速與低速事件(jian)輸入,以(yi)及(ji)可以(yi)避免在(zai)低輸入電壓(ya)下(xia)工作(zuo)的(de)電源電壓(ya)過(guo)低偵測等(deng)) ,NCP1396 的(de)獨(du)特(te)架(jia)構包括(kuo)一(yi)(yi)個(ge)500 kHz 的(de)壓(ya)控(kong)振(zhen)蕩器,由于在(zai)諧振(zhen)電路(lu)(lu)結(jie)構中避開(kai)諧振(zhen)尖峰相當重(zhong)要,因此為了(le)(le)將轉換器安(an)排在(zai)正確(que)(que)的(de)工作(zuo)區(qu),NCP1396 內置了(le)(le)可調(diao)整(zheng)且精確(que)(que)的(de)最低開(kai)關頻(pin)率,通(tong)過(guo)專(zhuan)有(you)高電壓(ya)技(ji)術支持。 應(ying)用S3F84K4 單片機實(shi)現智能充電器控(kong)制。

3 軟件設計(ji)

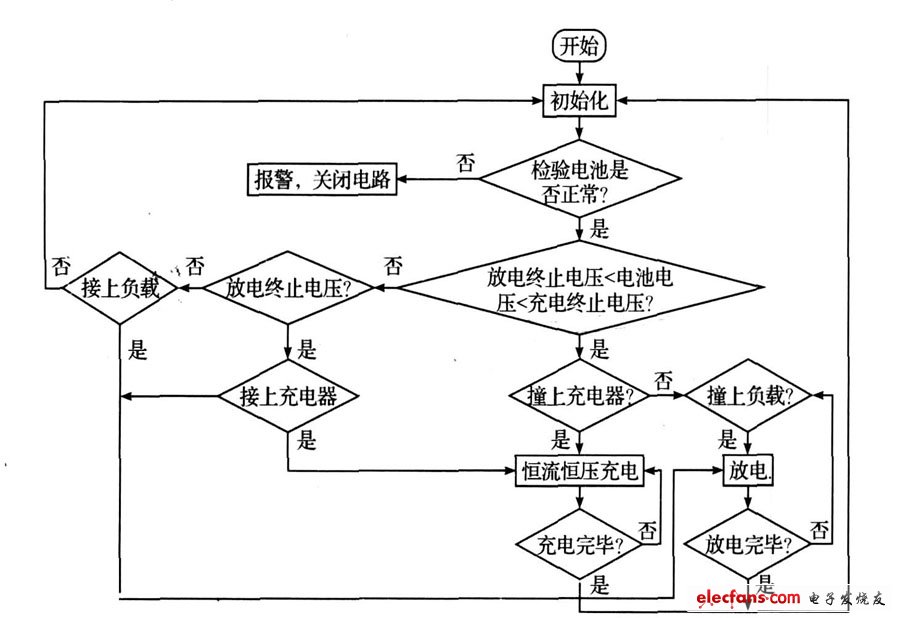

為滿(man)足充電(dian)要求, 該充電(dian)器(qi)軟件設計(ji)除了完成充放電(dian)控制外, 還具(ju)有過(guo)(guo)流(liu)(liu)保護、過(guo)(guo)壓保護、過(guo)(guo)溫保護、短(duan)路(lu)報(bao)警等功能模塊。主程序流(liu)(liu)程圖如(ru)圖6 所示。

圖6 主程序流程圖。

程序開(kai)始(shi)執行(xing)(xing)后, 首先進(jin)行(xing)(xing)初始(shi)化(hua)并檢(jian)測(ce)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)、電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流、溫(wen)度等(deng)信(xin)息是(shi)否正常。 如正常則(ze)進(jin)入(ru)下(xia)一步。 否則(ze)報(bao)警并關(guan)閉電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路。 如果(guo)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)在(zai)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)終(zhong)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)和放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)終(zhong)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)之(zhi)間, 說(shuo)明電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池既可充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)也(ye)可放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)。 此時(shi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路將判斷(duan)接(jie)上充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)機還是(shi)接(jie)上負載。 以(yi)進(jin)行(xing)(xing)相應的(de)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)和放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)。 如果(guo)兩(liang)者都沒(mei)有接(jie)則(ze)循環檢(jian)測(ce)過(guo)程。 若(ruo)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)已(yi)經(jing)到達充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)終(zhong)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)。 則(ze)等(deng)待負載的(de)接(jie)入(ru)進(jin)行(xing)(xing)放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian);同(tong)樣若(ruo)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya)己經(jing)達到放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)終(zhong)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)(ya),則(ze)等(deng)待充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)器的(de)接(jie)入(ru)以(yi)進(jin)行(xing)(xing)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)。 在(zai)整個(ge)過(guo)程中(zhong),該電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路將始(shi)終(zhong)實(shi)時(shi)檢(jian)測(ce)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池信(xin)息,若(ruo)有異常情況(kuang)發生(sheng),則(ze)立即利用(yong)中(zhong)斷(duan)信(xin)號(hao)終(zhong)止(zhi)正在(zai)進(jin)行(xing)(xing)的(de)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)或者放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)過(guo)程,關(guan)斷(duan)充(chong)(chong)放(fang)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)回(hui)路,同(tong)時(shi)進(jin)行(xing)(xing)報(bao)警并提(ti)示報(bao)警原因。

4 測試結果

本(ben)充電器的各項指標如下(xia):

(1) 輸入(ru)電流:50/ 60 Hz。

(2) AC/ DC 輸(shu)出(chu)電壓48 :V , AC/ DC 輸(shu)出(chu)電流:5. 0 A。

(3) 恒流(liu)充電電流(liu):4. 5 A。

(4) 恒壓充電(dian)電(dian)壓:45 V (AC)。

(5) 環境(jing)溫度: - 5~45 ℃。

經分析, 按(an)上述設計(ji)和分析結果(guo), 最后(hou)選定LLC 的參數Cr = 0. 043 055μF,Lr = 72. 636 09μH,Lm = 435. 816 5μH。

本智能充電器經測試,充電保護措施可靠,充電狀態準確,充電時間約為6 h ,如果需要進一步縮短充電時間,只需在初始化時設定更大的充電電流即可。 因為(wei)采用PWM 控制器(qi),所(suo)以(yi),充(chong)(chong)電(dian)效率(lv)可以(yi)達到92 %以(yi)上,最低時在85 %左右。根(gen)據(ju)實際需要(yao),要(yao)想(xiang)達到理想(xiang)的充(chong)(chong)電(dian)效率(lv),對充(chong)(chong)器(qi)件做(zuo)進一步的精(jing)確(que)要(yao)求。

在智能充電器控制系統設計過程中,主要側重點是保證充電器對(dui)充電(dian)(dian)(dian)電(dian)(dian)(dian)池電(dian)(dian)(dian)壓的(de)(de)精確控制,設計中元器(qi)(qi)件(jian)的(de)(de)選型也(ye)都是圍繞著這個重點來完成(cheng)的(de)(de)經過(guo)實驗電(dian)(dian)(dian)路(lu)(lu)的(de)(de)實際測試,由電(dian)(dian)(dian)源變壓器(qi)(qi)、整流電(dian)(dian)(dian)路(lu)(lu)、濾波電(dian)(dian)(dian)路(lu)(lu)及穩壓電(dian)(dian)(dian)路(lu)(lu)構成(cheng)AC/ DC 變換電(dian)(dian)(dian)路(lu)(lu)。 在NCP1653 、NCP1396 與S3F84 K4 的(de)(de)配合控制下可實現很(hen)高的(de)(de)系統精度(du)。