電動車用48V (20A?h)蓄電池充電器

在研究電動車用蓄電池特性及其充電策略和充電算法的基礎上,研制了一款基于P IC16C712單片機的4段式(涓流短時充電、恒流快速充電、恒壓均衡充電、浮充電) 48V (20A?h)蓄電池充電器。該充電(dian)(dian)器能(neng)夠對充電(dian)(dian)過程進(jin)行(xing)實時監測(ce)與控(kong)制,使充電(dian)(dian)過程按設定的理想充電(dian)(dian)曲線(xian)進(jin)行(xing)。測(ce)試表明(ming),該充電(dian)(dian)器既能(neng)完成(cheng)快速充電(dian)(dian)又能(neng)對蓄(xu)電(dian)(dian)池進(jin)行(xing)有(you)效的保護。

近年來,電動(dong)車作為一種(zhong)新型的(de)(de)綠色交通工具得到了迅猛的(de)(de)發展(zhan),并呈(cheng)現出向大功(gong)率、高速化和功(gong)能(neng)(neng)多樣化的(de)(de)發展(zhan)趨勢。因(yin)此,電動(dong)車對蓄(xu)電池的(de)(de)使用壽命、續行里程等性能(neng)(neng)提(ti)出的(de)(de)要求比以往更加苛(ke)刻。實驗(yan)研究表明:影響蓄(xu)電池性能(neng)(neng)的(de)(de)因(yin)素多種(zhong)多樣,如電動(dong)車的(de)(de)裝配性能(neng)(neng)、行駛電流、充電策略等。

其(qi)中蓄電(dian)(dian)(dian)(dian)池(chi)(chi)的充(chong)電(dian)(dian)(dian)(dian)過(guo)(guo)程(cheng)對其(qi)壽命影(ying)響最(zui)大,過(guo)(guo)充(chong)電(dian)(dian)(dian)(dian)、充(chong)電(dian)(dian)(dian)(dian)不足(zu)是引起蓄電(dian)(dian)(dian)(dian)池(chi)(chi)故(gu)障的主要原因(yin)。所以,必(bi)須(xu)通過(guo)(guo)設計合理的充(chong)電(dian)(dian)(dian)(dian)策略和充(chong)電(dian)(dian)(dian)(dian)算(suan)法以有效地減(jian)少蓄電(dian)(dian)(dian)(dian)池(chi)(chi)的損傷、減(jian)少充(chong)電(dian)(dian)(dian)(dian)損耗、提高(gao)充(chong)電(dian)(dian)(dian)(dian)速度。

為此,開發一種具有自主知識產權,具備適用功率大( 100 ~500W ) 、性能可靠等特點的電動車用48V (20A?h)蓄電池充電器以滿足電動摩托車、卡丁車、沙地車等電動車發展的迫切需要。該充電器以P IC16C712作為實時監控和中心控制單元,采用PWM DC-DC全橋變換器作為主電路,使得該充電器能夠根據蓄電池的充電特性自動調節輸出電壓、電流,進行智能充電,并且能夠對充電器的(de)運行狀態進行實(shi)時監測,若有(you)異常(chang),能(neng)及時地進行保護。此外,該充電(dian)器還具有(you)體積小、重量輕、精度高、充電(dian)速(su)度快(kuai)、性能(neng)穩定等顯(xian)著優點。

1 充電(dian)器原理(li)與硬件(jian)設計

1. 1 總體(ti)設計

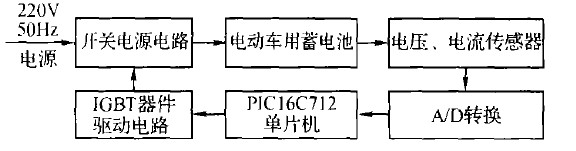

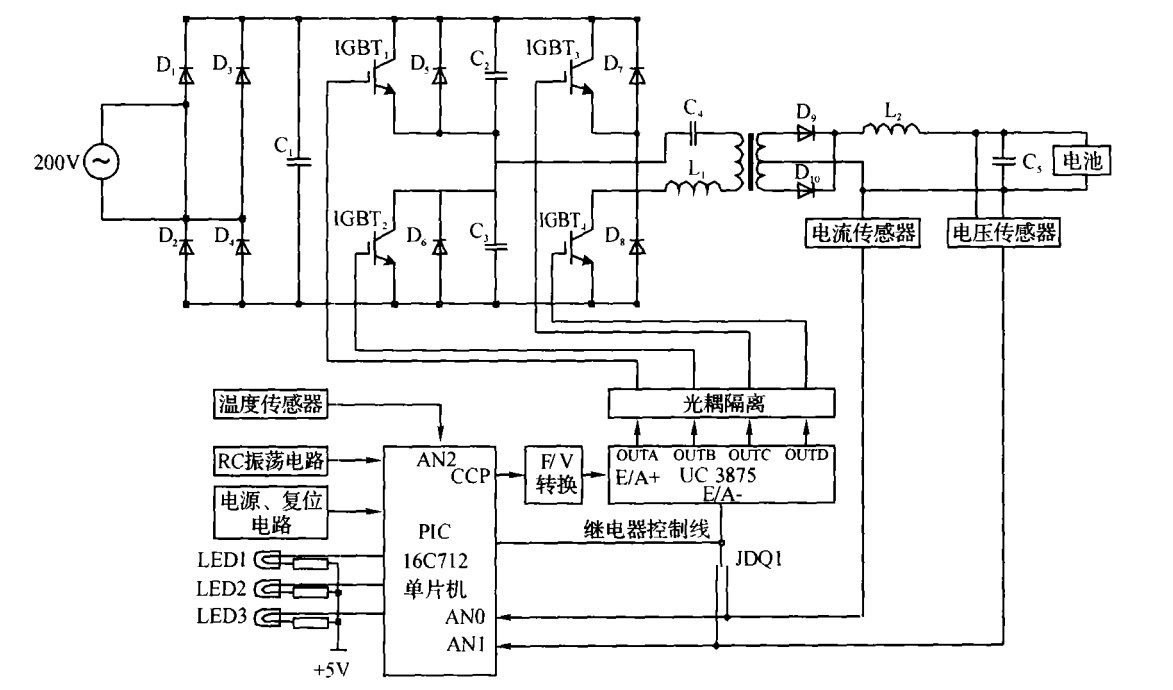

目前(qian),電(dian)(dian)(dian)動(dong)車電(dian)(dian)(dian)池(chi)作為一種儲能裝置,主(zhu)要以鉛酸(suan)蓄電(dian)(dian)(dian)池(chi)為主(zhu),充(chong)電(dian)(dian)(dian)器是專門針對鉛酸(suan)蓄電(dian)(dian)(dian)池(chi)所設計的(de)(de)。傳統的(de)(de)蓄電(dian)(dian)(dian)池(chi)充(chong)電(dian)(dian)(dian)器采用電(dian)(dian)(dian)流/電(dian)(dian)(dian)壓負反饋的(de)(de)方法(fa)來(lai)達到恒流/恒壓充(chong)電(dian)(dian)(dian)的(de)(de)目的(de)(de),為了實(shi)現充(chong)電(dian)(dian)(dian)過程各(ge)種工作參量(liang)的(de)(de)實(shi)時(shi)監(jian)測及(ji)智能多段式充(chong)電(dian)(dian)(dian)策略的(de)(de)精確控(kong)制,引入(ru)電(dian)(dian)(dian)流/電(dian)(dian)(dian)壓反饋環(huan),應用P IC16C712 單片機及(ji)相(xiang)應的(de)(de)控(kong)制電(dian)(dian)(dian)路(lu),其(qi)硬件結構框圖如(ru)(ru)圖1所示(shi),電(dian)(dian)(dian)路(lu)圖如(ru)(ru)圖2所示(shi)。

圖1 硬件結構框圖

圖2 電(dian)路原(yuan)理圖

由圖(tu)1和(he)圖(tu)2可以看(kan)出,蓄電(dian)(dian)(dian)池(chi)充電(dian)(dian)(dian)器主要由開關電(dian)(dian)(dian)源單元(電(dian)(dian)(dian)源變壓器、整流電(dian)(dian)(dian)路及濾波電(dian)(dian)(dian)路)和(he)監測與控(kong)(kong)制單元(傳感器、電(dian)(dian)(dian)源專用集(ji)成芯片UC3875及微控(kong)(kong)制器P IC16C712)兩部分組(zu)成。

在開(kai)關電(dian)(dian)(dian)源單元,單相(xiang)220V /50Hz的交(jiao)流(liu)電(dian)(dian)(dian)需(xu)經過(guo)全橋(qiao)整(zheng)流(liu)及大電(dian)(dian)(dian)容(rong)低頻濾(lv)(lv)波穩壓(ya),然后(hou)經過(guo)4只(zhi)IGBT器(qi)件IGBTl ~ IGBT4 組成的全橋(qiao)逆變(bian)器(qi)可(ke)(ke)得到(dao)(dao)脈寬可(ke)(ke)調的高頻交(jiao)流(liu)電(dian)(dian)(dian)。經高頻變(bian)壓(ya)器(qi)耦合到(dao)(dao)副邊,再經整(zheng)流(liu)管D9 和D10整(zheng)流(liu)和電(dian)(dian)(dian)感L2、電(dian)(dian)(dian)容(rong)C5 濾(lv)(lv)波,由此(ci)可(ke)(ke)以(yi)得到(dao)(dao)大小可(ke)(ke)變(bian)的低紋(wen)波直流(liu)電(dian)(dian)(dian)壓(ya)。

根(gen)據實(shi)際需要(yao),監測與控制單(dan)元選擇的(de)(de)(de)單(dan)片(pian)機型(xing)號是由(you)M ICROCH IP公司(si)(si)推出(chu)的(de)(de)(de)P IC16C712,其內部(bu)有(you)容量為1KB ×14 的(de)(de)(de)EPROM、128 ×8 的(de)(de)(de)RAM,此外(wai),還包(bao)括(kuo)4個8位A /D, 3個定時器(qi)(qi)和1個CCP模塊(kuai)(kuai)。充電器(qi)(qi)的(de)(de)(de)電壓和電流(liu)(liu)(liu)控制信號是由(you)P IC16C712的(de)(de)(de)CCP模塊(kuai)(kuai)輸(shu)出(chu),經(jing)過F /V轉(zhuan)換之(zhi)后(hou)輸(shu)入到(dao)由(you)美國Unitrode公司(si)(si)生產的(de)(de)(de)移相(xiang)式開關電源專用集成芯片(pian)UC3875的(de)(de)(de)誤差放大器(qi)(qi)輸(shu)入端(duan)(duan)E /A + ,反相(xiang)輸(shu)入端(duan)(duan)E /A - 接(jie)主電路輸(shu)出(chu)直流(liu)(liu)(liu)電流(liu)(liu)(liu)或直流(liu)(liu)(liu)電壓反饋信號,二者之(zhi)間(jian)的(de)(de)(de)切(qie)換由(you)P IC16C712單(dan)片(pian)機控制中間(jian)繼電器(qi)(qi)實(shi)現。

1. 2 溫度信(xin)號采集(ji)電路

在充(chong)電(dian)(dian)過(guo)程中,蓄電(dian)(dian)池的溫度(du)是一個非常(chang)重要的參(can)數。因(yin)為(wei)鉛酸蓄電(dian)(dian)池的電(dian)(dian)壓具有負溫度(du)系數,其值為(wei)- 4mV /℃,對于一個在環(huan)境溫度(du)為(wei)25℃時工(gong)作很(hen)理(li)想的充(chong)電(dian)(dian)器在環(huan)境溫度(du)降到0℃時,蓄電(dian)(dian)池將(jiang)出現(xian)充(chong)電(dian)(dian)不足的現(xian)象;而當環(huan)境溫度(du)升高到50℃時,蓄電(dian)(dian)池將(jiang)出現(xian)過(guo)充(chong)電(dian)(dian)的現(xian)象,這將(jiang)導致蓄電(dian)(dian)池壽命縮短。

因此,設計(ji)良(liang)好的(de)充電(dian)(dian)器(qi)應具有溫(wen)度(du)(du)檢測功能(neng)并能(neng)夠根據不同的(de)環境溫(wen)度(du)(du)調(diao)整充電(dian)(dian)過(guo)程中的(de)各(ge)轉換電(dian)(dian)壓值;同時,充電(dian)(dian)器(qi)還應具備溫(wen)度(du)(du)保護功能(neng),在充電(dian)(dian)過(guo)程中,當蓄電(dian)(dian)池(chi)溫(wen)度(du)(du)超出(chu)(chu)限定的(de)溫(wen)度(du)(du)范圍時充電(dian)(dian)器(qi)應立即(ji)停止充電(dian)(dian)或進入(ru)涓(juan)流充電(dian)(dian),并且(qie)PIC16C712應點亮故(gu)障(zhang)指示燈以(yi)提示用戶出(chu)(chu)現(xian)何種異常。

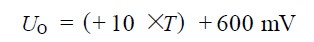

由上(shang)分(fen)析可知,溫度(du)檢(jian)測的(de)準確性(xing)將在很大程度(du)上(shang)影響(xiang)充電器的(de)性(xing)能。為(wei)(wei)此,利用LM61B IM3溫度(du)傳感器設計了溫度(du)檢(jian)測電路,如圖3所示(shi),該傳感器可以測量的(de)溫度(du)范圍(wei)為(wei)(wei)- 25℃~ + 85℃,線性(xing)度(du)為(wei)(wei)10mV /℃,即(ji):

圖3 溫度采集電路圖

2 充(chong)電策(ce)略(lve)與(yu)算法設計

2. 1 充(chong)電(dian)流(liu)程(cheng)

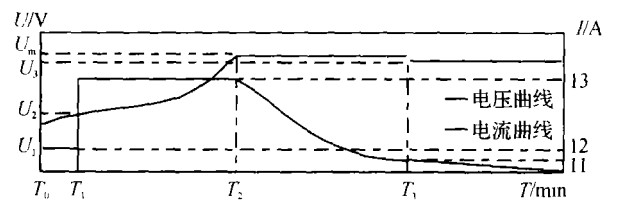

根(gen)據鉛酸蓄電(dian)(dian)(dian)(dian)池的(de)(de)特點(dian),將其充(chong)電(dian)(dian)(dian)(dian)過程分為(wei)4個階(jie)(jie)段(duan)(duan):涓流短時充(chong)電(dian)(dian)(dian)(dian)、恒流快速充(chong)電(dian)(dian)(dian)(dian)、恒壓均(jun)衡充(chong)電(dian)(dian)(dian)(dian)、浮充(chong)電(dian)(dian)(dian)(dian)。其中(zhong)第一階(jie)(jie)段(duan)(duan)和第二階(jie)(jie)段(duan)(duan)均(jun)為(wei)恒流充(chong)電(dian)(dian)(dian)(dian),采取這(zhe)種策略是因(yin)為(wei)實驗(yan)研究證明多段(duan)(duan)恒流充(chong)電(dian)(dian)(dian)(dian)有利于充(chong)入更多的(de)(de)電(dian)(dian)(dian)(dian)量且可以減少對蓄電(dian)(dian)(dian)(dian)池的(de)(de)損傷、延長(chang)使用壽命。充(chong)電(dian)(dian)(dian)(dian)過程中(zhong)各個階(jie)(jie)段(duan)(duan)充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)壓、充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流隨時間變(bian)化的(de)(de)曲線(xian)如圖4所示。

圖4 充電流程曲(qu)線。

(1)涓流短時充電( T0 - T1 )

蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)在(zai)(zai)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)初期可(ke)能(neng)(neng)已(yi)處于深度放電(dian)(dian)(dian)(dian)(dian)(dian)狀態(或可(ke)能(neng)(neng)已(yi)經處于受損的(de)(de)(de)(de)狀態) ,為(wei)避(bi)免對蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)過(guo)大(da)造成(cheng)"熱失控", P IC16C712單片機通過(guo)實時監測蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)的(de)(de)(de)(de)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya),對蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)進行穩定的(de)(de)(de)(de)小電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)涓流(liu)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian),這(zhe)樣有利(li)于激(ji)活(huo)蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)內的(de)(de)(de)(de)反應(ying)物質,部分恢復受損的(de)(de)(de)(de)蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)單元(yuan)。在(zai)(zai)涓流(liu)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)階段(duan),蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)開(kai)始(shi)緩(huan)慢(man)上(shang)升,當蓄(xu)電(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)上(shang)升到能(neng)(neng)接受大(da)電(dian)(dian)(dian)(dian)(dian)(dian)流(liu)充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)的(de)(de)(de)(de)閾值時則轉入恒流(liu)快速充(chong)(chong)電(dian)(dian)(dian)(dian)(dian)(dian)階段(duan)。

(2)恒流(liu)快速充電(dian)( T1 - T2 )

該階(jie)段充(chong)電電流(liu)保持恒定,蓄(xu)電池(chi)電壓上(shang)升(sheng)(sheng)較快,當(dang)電壓上(shang)升(sheng)(sheng)至(zhi)均衡充(chong)電壓閾值時,則轉入恒壓均衡充(chong)電階(jie)段。

(3)恒壓均衡充電(dian)( T2 - T3 )

該階段充(chong)(chong)電(dian)電(dian)壓保(bao)持恒定,蓄(xu)電(dian)池容量快速恢復。充(chong)(chong)電(dian)電(dian)流逐漸(jian)減小,當電(dian)流下(xia)降至某一閾值(zhi)時,自動轉入浮充(chong)(chong)電(dian)階段。

(4)浮充電( T3 - )

該階段主要用來補(bu)充蓄(xu)電池自(zi)放(fang)電所消耗的能(neng)量,此(ci)時標志著(zhu)充電過(guo)程結束。

2. 2 關鍵技(ji)術

2. 2. 1 恒流充電電流的選擇

充電(dian)(dian)過程中(zhong)包含兩(liang)個恒(heng)流充電(dian)(dian)過程:涓(juan)流短(duan)時充電(dian)(dian)和恒(heng)流快速(su)充電(dian)(dian)。

涓流(liu)短時充電電流(liu)的選擇應(ying)該(gai)根據(ju)蓄電池(chi)的剩余電量進行選擇。經過大量的實驗研究表明(ming),對于放電深度為(wei)80% ~100%的蓄電池(chi),充電電流(liu)定在0. 2~0. 4A比較合適。

恒流快速充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流的(de)選(xuan)擇(ze)要綜合(he)考慮蓄(xu)電(dian)(dian)(dian)(dian)池容(rong)量、內阻、對(dui)(dui)充(chong)電(dian)(dian)(dian)(dian)時間的(de)要求、制造成本等(deng)多方面因(yin)素(su)。按照(zhao)應用(yong)經(jing)驗,普(pu)遍認為(wei),該充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流設置為(wei)0. 15~0. 3 C對(dui)(dui)蓄(xu)電(dian)(dian)(dian)(dian)池比較合(he)適。電(dian)(dian)(dian)(dian)動自行車用(yong)48V (20A?h)鉛酸蓄(xu)電(dian)(dian)(dian)(dian)池時采用(yong)的(de)是20℃標(biao)稱,但是實際容(rong)量往往只能達到15~17A?h.因(yin)此,依據該經(jing)驗看(kan)法,充(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流應大致定在2. 25~5. 1 A之(zhi)間,平均為(wei)3. 675A.

有(you)(you)設(she)計者認為(wei)減(jian)小(xiao)充(chong)(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)具有(you)(you)3個方面(mian)的(de)(de)優點: (1)可(ke)(ke)以(yi)(yi)(yi)(yi)(yi)使(shi)單位時間內產生的(de)(de)熱量降低(di),有(you)(you)利于(yu)在蓄電(dian)(dian)(dian)(dian)池的(de)(de)使(shi)用壽(shou)命(ming)末期和夏(xia)季保證充(chong)(chong)電(dian)(dian)(dian)(dian)質量;(2)可(ke)(ke)以(yi)(yi)(yi)(yi)(yi)減(jian)少極化(hua)(hua)(歐姆極化(hua)(hua)、濃差(cha)極化(hua)(hua)、電(dian)(dian)(dian)(dian)化(hua)(hua)學極化(hua)(hua))現象的(de)(de)影響,有(you)(you)利于(yu)冬季充(chong)(chong)電(dian)(dian)(dian)(dian); ( 3)可(ke)(ke)以(yi)(yi)(yi)(yi)(yi)降低(di)充(chong)(chong)電(dian)(dian)(dian)(dian)器的(de)(de)輸(shu)出功率,制(zhi)造成本下(xia)降。但是也有(you)(you)設(she)計者認為(wei),電(dian)(dian)(dian)(dian)動車用蓄電(dian)(dian)(dian)(dian)池以(yi)(yi)(yi)(yi)(yi)較大(da)電(dian)(dian)(dian)(dian)流(liu)短時間放電(dian)(dian)(dian)(dian),充(chong)(chong)電(dian)(dian)(dian)(dian)接受(shou)率高, 所(suo)以(yi)(yi)(yi)(yi)(yi)可(ke)(ke)以(yi)(yi)(yi)(yi)(yi)增(zeng)大(da)充(chong)(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)(甚至推(tui)薦為(wei)5A)以(yi)(yi)(yi)(yi)(yi)提高充(chong)(chong)電(dian)(dian)(dian)(dian)速度(du)。

通過對(dui)浙江(jiang)(jiang)天能(neng)、浙江(jiang)(jiang)超威、英國IBT和日本松下等電(dian)(dian)動車(che)用48V ( 20A?h)蓄電(dian)(dian)池進行了長(chang)期的(de)可靠(kao)性實驗。在(zai)充電(dian)(dian)時,采用平(ping)均值為(wei)3. 5A并根(gen)據環境(jing)溫度動態小(xiao)幅度調整的(de)恒流(liu)快速充電(dian)(dian)電(dian)(dian)流(liu),蓄電(dian)(dian)池沒有明顯發熱,充電(dian)(dian)過程穩定可靠(kao)。

2. 2. 2 恒壓充(chong)電電壓的選擇

恒壓充(chong)電電壓的(de)選(xuan)擇(ze)非(fei)常關鍵,因為它不(bu)能在很寬的(de)范圍內調整。確定這個參數不(bu)但(dan)需要對(dui)蓄電池有較為深(shen)人(ren)的(de)了解,還需要對(dui)充(chong)電策略等因素進(jin)行考慮。

蓄(xu)電(dian)池(chi)(chi)在(zai)(zai)充(chong)電(dian)時,正極上的(de)析氧(yang)速(su)(su)率與施加的(de)充(chong)電(dian)電(dian)壓(ya)成正比,而(er)氧(yang)傳輸到負(fu)極并溶解在(zai)(zai)負(fu)極表面液膜中(zhong)進行(xing)還(huan)原的(de)速(su)(su)度(du)受到限(xian)制,即氧(yang)的(de)析出快(kuai)于還(huan)原時,復合(he)效率就(jiu)下降,造成失(shi)水。通常(chang)情況下, 48V 閥控鉛酸蓄(xu)電(dian)池(chi)(chi)的(de)浮充(chong)電(dian)壓(ya)設置在(zai)(zai)55 -55. 6 V,可以保證蓄(xu)電(dian)池(chi)(chi)長期處于充(chong)電(dian)狀態且極少失(shi)水。循環(huan)使(shi)用(yong)蓄(xu)電(dian)池(chi)(chi)最高充(chong)電(dian)電(dian)壓(ya)為58. 8V,如果超過就(jiu)會使(shi)復合(he)效率急劇下降,從而(er)影響(xiang)電(dian)池(chi)(chi)的(de)使(shi)用(yong)壽命(ming)。

2. 2. 3 蓄(xu)電池是否(fou)充滿的(de)判定(ding)

對(dui)蓄(xu)電(dian)池(chi)(chi)在充(chong)(chong)(chong)電(dian)過(guo)程(cheng)中是否(fou)已充(chong)(chong)(chong)滿的判(pan)斷(duan)是充(chong)(chong)(chong)電(dian)器的重要指標。如果蓄(xu)電(dian)池(chi)(chi)未充(chong)(chong)(chong)滿而錯判(pan)為充(chong)(chong)(chong)滿將導(dao)致(zhi)蓄(xu)電(dian)池(chi)(chi)欠充(chong)(chong)(chong);反之,則將導(dao)致(zhi)蓄(xu)電(dian)池(chi)(chi)過(guo)充(chong)(chong)(chong)。這兩種情況都會嚴(yan)重影響(xiang)蓄(xu)電(dian)池(chi)(chi)的壽(shou)命。目前(qian)判(pan)斷(duan)蓄(xu)電(dian)池(chi)(chi)是否(fou)充(chong)(chong)(chong)滿的控(kong)制(zhi)準則有(you):定時控(kong)制(zhi)、電(dian)壓控(kong)制(zhi)(包(bao)(bao)含(han)最(zui)高(gao)電(dian)壓、電(dian)壓負(fu)增量、電(dian)壓零增量等(deng))、溫(wen)度控(kong)制(zhi)(包(bao)(bao)括最(zui)高(gao)溫(wen)度、最(zui)高(gao)溫(wen)升、溫(wen)度變化(hua)率等(deng))、電(dian)流控(kong)制(zhi)(包(bao)(bao)含(han)最(zui)小電(dian)流、電(dian)流變化(hua)量等(deng))、動態內阻控(kong)制(zhi)等(deng)。

在(zai)實際應用(yong)中,如(ru)果以單一的(de)(de)(de)控(kong)制(zhi)的(de)(de)(de)方式都(dou)(dou)將不(bu)可避免地存在(zai)缺(que)陷(xian)。比如(ru),在(zai)恒(heng)(heng)壓(ya)均(jun)衡充電(dian)(dian)過程(cheng)中,電(dian)(dian)壓(ya)保持恒(heng)(heng)定(ding)(ding)(ding),電(dian)(dian)流(liu)(liu)(liu)(liu)會隨(sui)著充電(dian)(dian)的(de)(de)(de)進程(cheng)逐漸減小,當小到一定(ding)(ding)(ding)程(cheng)度電(dian)(dian)流(liu)(liu)(liu)(liu)將會恒(heng)(heng)定(ding)(ding)(ding),不(bu)再下(xia)降,這(zhe)(zhe)時的(de)(de)(de)電(dian)(dian)能(neng)向化(hua)學能(neng)的(de)(de)(de)轉化(hua)效率已經(jing)很低,電(dian)(dian)能(neng)主要用(yong)于電(dian)(dian)解水,一般認為(wei)這(zhe)(zhe)個(ge)電(dian)(dian)流(liu)(liu)(liu)(liu)為(wei)蓄電(dian)(dian)池恒(heng)(heng)壓(ya)均(jun)衡充電(dian)(dian)的(de)(de)(de)殘余(yu)(yu)電(dian)(dian)流(liu)(liu)(liu)(liu)。然而,殘余(yu)(yu)電(dian)(dian)流(liu)(liu)(liu)(liu)的(de)(de)(de)大小將隨(sui)著環境溫度的(de)(de)(de)變化(hua)而變化(hua),也就是(shi)說(shuo)殘余(yu)(yu)電(dian)(dian)流(liu)(liu)(liu)(liu)是(shi)一個(ge)受內(nei)、外界多重因(yin)素影響的(de)(de)(de)動態值(zhi)。若沒有溫度控(kong)制(zhi),最高充電(dian)(dian)電(dian)(dian)壓(ya)和切(qie)換(huan)電(dian)(dian)流(liu)(liu)(liu)(liu)都(dou)(dou)只(zhi)能(neng)設置(zhi)成定(ding)(ding)(ding)值(zhi),而這(zhe)(zhe)個(ge)定(ding)(ding)(ding)值(zhi)無論如(ru)何設置(zhi),都(dou)(dou)只(zhi)能(neng)在(zai)一個(ge)相對較小的(de)(de)(de)范圍內(nei)成為(wei)最佳設置(zhi)。為(wei)此,設計的(de)(de)(de)充電(dian)(dian)器通過對電(dian)(dian)壓(ya)、電(dian)(dian)流(liu)(liu)(liu)(liu)、溫度等工作(zuo)參(can)數(shu)進行(xing)實時檢測,并按模(mo)糊理論的(de)(de)(de)評判規則對這(zhe)(zhe)些(xie)參(can)數(shu)進行(xing)綜(zong)合分析(xi),從而確定(ding)(ding)(ding)蓄電(dian)(dian)池是(shi)否充滿。

2. 3 軟件架構

P IC16C712單(dan)片機的軟件模塊主要完成對傳感器的輸入信號進(jin)(jin)行(xing)采集、對電(dian)源專用(yong)芯片UC3875進(jin)(jin)行(xing)控制(zhi)、對異常進(jin)(jin)行(xing)處(chu)理(li)等工作。在設計過程中,軟件系統每隔(ge)10 s檢測(ce)一(yi)次(ci)(ci)電(dian)壓和電(dian)流; 每隔(ge)20 s檢測(ce)一(yi)次(ci)(ci)溫度(du)。如有異常,系統將通過LED提示用(yong)戶出現何種(zhong)異常并采取(qu)相應的保護措施(shi)。整個系統的軟件架構,如圖5所示。

圖5 軟件架構

對充電器樣機進行的測試表明蓄電池充電器具有如(ru)下特(te)性:

(1)輸入電壓: 220 Vac;

(2)輸出電壓(ya): 40~60V;

(3)輸出電流: < 10A;

(4)功(gong)率(lv)因數: > 0. 99;

(5)充電(dian)噪聲: < 20dB;

(6)充(chong)電(dian)時間(jian): 6~8h;

(7)充電效率: > 85%;

(8)充電溫升: < 15℃;

(9)質 量(liang): < 0. 6kg.

此外,充電器還具有故障診斷功能。當充電回路電流或電壓過大、開路、短路時,充電器自(zi)動切(qie)斷主電路(lu),同時點亮(liang)相(xiang)應的LED故(gu)障(zhang)指示(shi)燈指示(shi)故(gu)障(zhang)原因,具有良好的保護特性。