鋰電池充電器測試小方案

鋰離子(Li+)電池比其它化學類型的電池更脆弱,對于違規操作具有非常小的容限。因此,鋰電池充電(dian)(dian)電(dian)(dian)路比較復雜,要求高精(jing)(jing)度電(dian)(dian)流、電(dian)(dian)壓設置。如果無法滿(man)足這(zhe)些精(jing)(jing)度要求,充電(dian)(dian)器可能(neng)無法將(jiang)電(dian)(dian)池(chi)(chi)完(wan)全充滿(man),進(jin)而(er)降低電(dian)(dian)池(chi)(chi)壽命,或影響(xiang)電(dian)(dian)池(chi)(chi)性能(neng)。

鑒于對Li+電池充電器的這些要(yao)求,對充(chong)電(dian)器設計進行(xing)完全測(ce)試(shi)并(bing)在整個(ge)工作(zuo)范(fan)圍內進行(xing)分段(duan)測(ce)試(shi)非常(chang)重要(yao)。然而,采用常(chang)規負載(zai)(即Li+電(dian)池(chi))測(ce)試(shi)Li+電(dian)池(chi)充(chong)電(dian)器將(jiang)非常(chang)耗時,而且在實(shi)驗室和(he)生產環境中也難于(yu)實(shi)現。為了簡化測(ce)試(shi)過程,本文給(gei)出了一個(ge)電(dian)池(chi)仿真電(dian)路(lu),可加快測(ce)試(shi)速度,在不(bu)帶實(shi)際電(dian)池(chi)的情況下實(shi)現對鋰離(li)子電(dian)池(chi)充(chong)電(dian)器的測(ce)試(shi)。

CC-CV充電

鋰離子(zi)電(dian)池(chi)充(chong)電(dian)過(guo)程的第一階段需要中等精度的恒(heng)流(CC)充(chong)電(dian),然后在第二(er)階段過(guo)渡(du)到高精度恒(heng)壓(ya)(CV)充(chong)電(dian)。

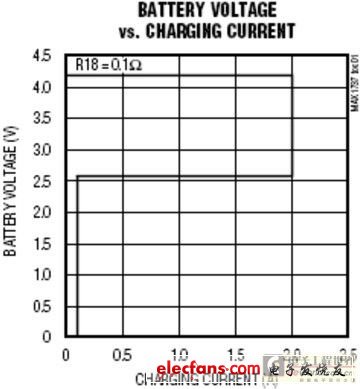

圖1為用于鋰(li)(li)離子電(dian)(dian)池(chi)充電(dian)(dian)器的CC-CV集成電(dian)(dian)路(MAX1737)的V-I特性(xing)曲(qu)線。這(zhe)種類型的IC是消費類產(chan)品中所(suo)有鋰(li)(li)離子電(dian)(dian)池(chi)充電(dian)(dian)器的核心。圖中可清(qing)楚

看出CC (2.6V至(zhi)4.2V電池電壓)和(he)CV (4.2V)區域。

圖1. MAX1737的V-I曲線是Li+電池充電器的標準特性曲線

電池低于2.6V時,需要采用不同的充電技術。如果試圖對放電至2.6V以下的電池充電,充電器須提供(gong)一(yi)個較低的(de)充(chong)(chong)電(dian)電(dian)流(liu)(“調(diao)理電(dian)流(liu)”),將(jiang)電(dian)池(chi)電(dian)壓充(chong)(chong)至(zhi)2.6V。這是鋰離(li)子電(dian)池(chi)過放電(dian)時所必須采取的(de)安全機(ji)制(zhi)。VBATT< 2.6V時強行(xing)進行(xing)快(kuai)速充(chong)(chong)電(dian),會使電(dian)池(chi)進入不(bu)可(ke)恢復的(de)短路狀態。

CC向(xiang)CV階段的(de)過(guo)渡(du)點的(de)臨界容(rong)差(cha)為± 40mV。之所以(yi)要求如此嚴格的(de)容(rong)差(cha),是因(yin)為如果CV過(guo)低,電(dian)(dian)(dian)(dian)池(chi)將無法完全充(chong)(chong)滿;而CV過(guo)高(gao),則會縮(suo)短電(dian)(dian)(dian)(dian)池(chi)的(de)使(shi)用壽命(ming)。充(chong)(chong)電(dian)(dian)(dian)(dian)過(guo)程終止意味著(zhu)檢(jian)測到電(dian)(dian)(dian)(dian)池(chi)達到滿電(dian)(dian)(dian)(dian)量,充(chong)(chong)電(dian)(dian)(dian)(dian)器必須斷開或關(guan)閉(bi)。在CV階段,當(dang)檢(jian)測到充(chong)(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流降至快充(chong)(chong)電(dian)(dian)(dian)(dian)流或最大充(chong)(chong)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流的(de)一(yi)定比例(通(tong)常< 10%)時(shi)終止充(chong)(chong)電(dian)(dian)(dian)(dian)。

Li+電(dian)池充電(dian)器參數測(ce)試

Li+電(dian)(dian)池(chi)充電(dian)(dian)器設計通(tong)常包(bao)括兩個基本(ben)部(bu)分(fen):數字(zi)部(bu)分(fen)(控制狀態機)和(he)模擬(ni)部(bu)分(fen),模擬(ni)部(bu)分(fen)包(bao)括帶有高精度(du)(>1%)基準、可精確(que)控制的電(dian)(dian)流/電(dian)(dian)壓源。對(dui)鋰離子(zi)充電(dian)(dian)器(不僅指IC)進行完全測(ce)試是一項非常棘(ji)手且耗費時間(jian)的工作(zuo),不僅僅限于對(dui)電(dian)(dian)流或電(dian)(dian)壓值進行檢(jian)驗。

測(ce)(ce)試(shi)時(shi)(shi)(shi)(shi),應該(gai)在(zai)整個(ge)工作范圍對充(chong)電(dian)(dian)(dian)器進(jin)行分段(duan)檢(jian)測(ce)(ce):包括(kuo)CC階(jie)段(duan)、從CC到CV的切換(huan)、充(chong)電(dian)(dian)(dian)終止(zhi)等。如上所述,測(ce)(ce)試(shi)的理想(xiang)情(qing)況是采(cai)用常(chang)規(gui)充(chong)電(dian)(dian)(dian)器的負(fu)載:即Li+電(dian)(dian)(dian)池。然而,由于充(chong)電(dian)(dian)(dian)過程需要(yao)一小時(shi)(shi)(shi)(shi)甚至更長(chang)時(shi)(shi)(shi)(shi)間(jian)(jian),使用鋰電(dian)(dian)(dian)池進(jin)行測(ce)(ce)試(shi)非常(chang)耗時(shi)(shi)(shi)(shi)。根(gen)據(ju)具體測(ce)(ce)試(shi)條件(jian)的不(bu)同:例如大容(rong)量電(dian)(dian)(dian)池+慢速充(chong)電(dian)(dian)(dian),小容(rong)量電(dian)(dian)(dian)池+快速充(chong)電(dian)(dian)(dian)以(yi)及其(qi)它(ta)可能組合,測(ce)(ce)試(shi)時(shi)(shi)(shi)(shi)間(jian)(jian)也(ye)不(bu)盡相同。

此外,充(chong)(chong)電(dian)(dian)(dian)過程(cheng)無法在保證不損(sun)壞電(dian)(dian)(dian)池的前提下提高(gao)充(chong)(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu),因為充(chong)(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu)受電(dian)(dian)(dian)池最大充(chong)(chong)電(dian)(dian)(dian)速率(即快(kuai)速充(chong)(chong)電(dian)(dian)(dian)電(dian)(dian)(dian)流(liu))的制約。對于消費類產品常用的電(dian)(dian)(dian)池,很少規定電(dian)(dian)(dian)流(liu)大于1C (在1小(xiao)(xiao)時內將電(dian)(dian)(dian)池完全(quan)放(fang)電(dian)(dian)(dian)的電(dian)(dian)(dian)流(liu))。因此,大多數(shu)情況下完成(cheng)整(zheng)個充(chong)(chong)電(dian)(dian)(dian)周期所需要的時間往往超過兩(liang)小(xiao)(xiao)時。如果需要重復(fu)測試,則需要將電(dian)(dian)(dian)池完全(quan)放(fang)電(dian)(dian)(dian) ― 這一過程(cheng)僅(jin)(jin)僅(jin)(jin)比充(chong)(chong)電(dian)(dian)(dian)稍微短一些(xie)。或(huo)者,必(bi)須能夠隨時備有完全(quan)放(fang)電(dian)(dian)(dian)的電(dian)(dian)(dian)池。

另外可以(yi)使用(yong)一個(ge)模擬的(de)理想負(fu)(fu)載(zai)替代真實電池(chi)進行(xing)負(fu)(fu)載(zai)測試。仿真時,應驗證電路的(de)直流響應和動態穩(wen)定性。然(ran)而,使用(yong)功率測試所用(yong)的(de)標(biao)準負(fu)(fu)載(zai)進行(xing)電池(chi)仿真非常困難。與(yu)大多數電源(yuan)測試使用(yong)的(de)負(fu)(fu)載(zai)不(bu)同,電池(chi)不(bu)能(neng)簡單地當作電阻或固定地吸入電流。如上所述,必須(xu)在整個(ge)工作范圍內進行(xing)分段測試。以(yi)下(xia)介紹的(de)Li+充電器測試電路完全滿足這些要求(qiu)。

選擇電池模型負載

我們先討論兩個必須考慮但最終放棄的建模方法。電池負載建模的方法之一是:使用一個具有源出(放電)和吸入(充電)電流能力的電壓源與代表電池內阻的電阻串聯。由于Li+電池要求精確控制終止電壓和充電電流,目前所有Li+充電器實際上(shang)是穩壓電源轉換器。

此外,由于穩壓電源變換器(充電器)的穩定性取決于負載(電池)的動態特性,因此必須選擇一個與模型非常相似的負載。否則,測試只能驗證充電器本身的V-I特性。

如(ru)果只(zhi)是進行一次性測試(shi)(shi),可以使用并聯型(xing)穩壓(ya)(ya)器與電(dian)(dian)(dian)(dian)阻串聯,這(zhe)足以模擬(ni)電(dian)(dian)(dian)(dian)池的(de)(de)內阻,并且,這(zhe)一簡(jian)單的(de)(de)電(dian)(dian)(dian)(dian)池模型(xing)完全可以滿(man)足測試(shi)(shi)要求。這(zhe)種方法(fa)的(de)(de)優勢是由充電(dian)(dian)(dian)(dian)器本(ben)身(shen)供電(dian)(dian)(dian)(dian)。然而(er),更(geng)嚴格的(de)(de)測試(shi)(shi)需要更(geng)精確(que)的(de)(de)模型(xing)。該模型(xing)采(cai)用內部(bu)電(dian)(dian)(dian)(dian)壓(ya)(ya)源,電(dian)(dian)(dian)(dian)壓(ya)(ya)值是充電(dian)(dian)(dian)(dian)過程中供給(gei)電(dian)(dian)(dian)(dian)池的(de)(de)總電(dian)(dian)(dian)(dian)荷的(de)(de)函數。

用恒(heng)流源(yuan)對電池(chi)充電時(shi)電壓(ya)將不(bu)斷(duan)變(bian)化(hua),以一定的(de)(de)(de)(de)正斜率(lv)上(shang)升。這是由于放電和其它(ta)電池(chi)內(nei)部化(hua)學變(bian)化(hua)過程(cheng)中,電池(chi)正極周圍累積的(de)(de)(de)(de)極化(hua)離子逐(zhu)漸減少。因此,充電器的(de)(de)(de)(de)工(gong)作(zuo)(zuo)點取(qu)決于電池(chi)連接時(shi)間的(de)(de)(de)(de)長短,以及電池(chi)的(de)(de)(de)(de)工(gong)作(zuo)(zuo)歷史(shi)。用大多數電子實(shi)驗室能夠找到的(de)(de)(de)(de)通用器件構建負載,以模(mo)擬(ni)這一復雜負載的(de)(de)(de)(de)模(mo)型很困難。

需要經常(chang)對充(chong)(chong)電(dian)(dian)電(dian)(dian)路(lu)進行(xing)測(ce)試(shi),或必須詳細描述電(dian)(dian)路(lu)特性時(shi)(shi)(shi)(shi),準確(que)模擬(ni)充(chong)(chong)電(dian)(dian)過(guo)程的(de)(de)電(dian)(dian)池(chi)非常(chang)有(you)用(yong)。模擬(ni)過(guo)程需要連續(xu)掃描充(chong)(chong)電(dian)(dian)器的(de)(de)所有(you)直流工作(zuo)點。模擬(ni)電(dian)(dian)路(lu)還(huan)要顯示(shi)結(jie)果,使操作(zuo)人員(yuan)可(ke)(ke)(ke)以(yi)查(cha)找問(wen)題(ti)、故(gu)障(zhang)和(he)干擾。如果模擬(ni)電(dian)(dian)路(lu)能(neng)夠提供(gong)電(dian)(dian)池(chi)電(dian)(dian)壓輸出和(he)信號,這些結(jie)果可(ke)(ke)(ke)以(yi)直接作(zuo)為示(shi)波器信號。測(ce)試(shi)速(su)(su)度可(ke)(ke)(ke)以(yi)加快(kuai)(kuai)(從幾小(xiao)時(shi)(shi)(shi)(shi)到數(shu)十秒(miao)),并(bing)可(ke)(ke)(ke)根據(ju)需要進行(xing)多次反復,比用(yong)真正的(de)(de)電(dian)(dian)池(chi)測(ce)試(shi)更方便。然而,測(ce)試(shi)速(su)(su)度加快(kuai)(kuai)后對確(que)定(ding)充(chong)(chong)電(dian)(dian)電(dian)(dian)源的(de)(de)熱效應不利(li)。因此,可(ke)(ke)(ke)能(neng)需要額外的(de)(de)長時(shi)(shi)(shi)(shi)間測(ce)試(shi),以(yi)便與充(chong)(chong)電(dian)(dian)電(dian)(dian)源和(he)調(diao)節電(dian)(dian)路(lu)的(de)(de)熱時(shi)(shi)(shi)(shi)間常(chang)數(shu)相吻合。

建立電池模型(xing)負(fu)載

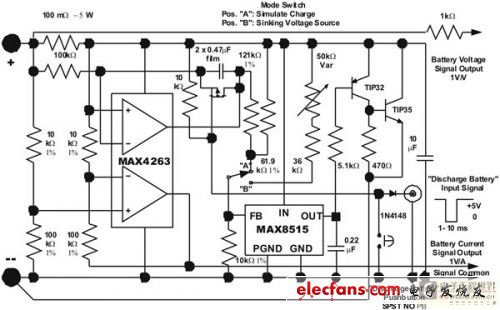

圖2電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路模(mo)擬(ni)的(de)是單節鋰離(li)子(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)。充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)器CC階(jie)段的(de)終(zhong)(zhong)止(zhi)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)和快速充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流由充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)器設(she)置(zhi)(zhi)決定。仿真器初始(shi)化時,可設(she)置(zhi)(zhi)完(wan)全放電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)條件下(xia)內部(bu)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)為3V,但該電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)可以提升(sheng)到(dao)4.3V,以測試(shi)過充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)情況(kuang)(kuang)。3V初始(shi)值通(tong)常用(yong)于低(di)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)關(guan)斷電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路(用(yong)來(lai)終(zhong)(zhong)止(zhi)鋰離(li)子(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)放電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)過程)。這種設(she)計(ji)專(zhuan)門針對(dui)終(zhong)(zhong)止(zhi)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)為4.2V的(de)標(biao)準CC-CV鋰離(li)子(zi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)器。該設(she)計(ji)調整起來(lai)很容易,能夠適應(ying)非(fei)標(biao)準終(zhong)(zhong)止(zhi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)和完(wan)全放電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)的(de)測試(shi)。測試(shi)時充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)器用(yong)高達3A的(de)充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流驅動仿真電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路,受功率晶體(ti)管功耗(hao)的(de)限制(zhi)。圖2電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路模(mo)擬(ni)了電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)增加的(de)情況(kuang)(kuang),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)池(chi)(chi)(chi)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)壓(ya)是從仿真電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路設(she)置(zhi)(zhi)為完(wan)全放電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)狀態開始(shi),電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)路充電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)(dian)(dian)(dian)(dian)流的(de)函數。

根(gen)據圖(tu)中給(gei)出的(de)參數值,充電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流為1A時,積分時間常數使模(mo)(mo)擬(ni)電(dian)(dian)(dian)(dian)路在6至7秒內(nei)(nei)達到充電(dian)(dian)(dian)(dian)器(qi)的(de)4.2V限制。對電(dian)(dian)(dian)(dian)流范圍、內(nei)(nei)阻、充電(dian)(dian)(dian)(dian)終止電(dian)(dian)(dian)(dian)壓和完全放電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)壓的(de)模(mo)(mo)擬(ni)是在鋰離子電(dian)(dian)(dian)(dian)池(本例中指Sony US18650G3)典型參數的(de)基礎上完成的(de)。所仿真(zhen)的(de)電(dian)(dian)(dian)(dian)池電(dian)(dian)(dian)(dian)壓沒有考慮環境溫度的(de)影響(xiang)。

圖2 單節Li+電(dian)(dian)(dian)(dian)池(chi)充電(dian)(dian)(dian)(dian)情(qing)(qing)況(kuang)的仿(fang)真電(dian)(dian)(dian)(dian)路(lu),該(gai)電(dian)(dian)(dian)(dian)路(lu)可以在不使用實際電(dian)(dian)(dian)(dian)池(chi)的情(qing)(qing)況(kuang)下測試Li+電(dian)(dian)(dian)(dian)池(chi)充電(dian)(dian)(dian)(dian)器

并聯(lian)穩壓器設計采用MAX8515并聯(lian)穩壓器和(he)一對(dui)雙極型(xing)功率晶體(ti)管(選(xuan)擇該穩壓器時考慮了其內部基準(zhun)電壓的精(jing)度),大電流TIP35晶體(ti)管安裝在(zai)能(neng)夠耗散25W熱(re)量(liang)的散熱(re)器上(shang)。

MAX4163雙運(yun)放的(de)(de)其中一個放大(da)器用來對(dui)充電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)流(liu)(liu)積分,另一個放大(da)器對(dui)電(dian)(dian)(dian)(dian)流(liu)(liu)測量信號進行放大(da)和偏置。該運(yun)算放大(da)器具有較(jiao)高(gao)的(de)(de)電(dian)(dian)(dian)(dian)源抑制比,并可支持滿擺幅輸入(ru)/輸出范圍,簡化了兩種功(gong)能電(dian)(dian)(dian)(dian)路的(de)(de)設(she)計。注意,與電(dian)(dian)(dian)(dian)池(chi)仿(fang)真器正端串聯的(de)(de)0.100Ω電(dian)(dian)(dian)(dian)流(liu)(liu)檢測電(dian)(dian)(dian)(dian)阻同時也作為電(dian)(dian)(dian)(dian)池(chi)內阻。

在具(ju)有自動測試-數據采集功能(neng)的系統內工作(zuo)時(shi),可(ke)用外部信號(hao)將仿真(zhen)電池復位到完全放電狀(zhuang)態。另(ling)外,手動操作(zuo)測試設置(zhi)時(shi),可(ke)用按鍵復位。

利用單刀單擲(zhi)(zhi)開關可以選擇仿(fang)(fang)真(zhen)(zhen)電(dian)(dian)(dian)池(chi)(chi)的(de)兩種工作(zuo)(zuo)模式。擲(zhi)(zhi)向(xiang)A端(duan)時(shi)(shi),實(shi)現(xian)積(ji)分充(chong)電(dian)(dian)(dian)仿(fang)(fang)真(zhen)(zhen)器(qi)(qi),如上(shang)所述(shu)。擲(zhi)(zhi)向(xiang)B端(duan)時(shi)(shi),仿(fang)(fang)真(zhen)(zhen)器(qi)(qi)將(jiang)設(she)定(ding)在(zai)(zai)某一(yi)(yi)固定(ding)的(de)直流(liu)工作(zuo)(zuo)點對充(chong)電(dian)(dian)(dian)器(qi)(qi)進(jin)行現(xian)場測試時(shi)(shi)的(de)輸出(chu)電(dian)(dian)(dian)壓(ya)(ya)(ya)和吸(xi)電(dian)(dian)(dian)流(liu)。為實(shi)現(xian)這一(yi)(yi)功能,“設(she)置(zhi)”電(dian)(dian)(dian)壓(ya)(ya)(ya)可通過改變50kΩ可變電(dian)(dian)(dian)阻(zu),在(zai)(zai)2.75V至5.75V之間手動調整。這些設(she)置(zhi)電(dian)(dian)(dian)壓(ya)(ya)(ya)值與內部吸(xi)入(ru)電(dian)(dian)(dian)流(liu)有關。仿(fang)(fang)真(zhen)(zhen)器(qi)(qi)端(duan)實(shi)測電(dian)(dian)(dian)壓(ya)(ya)(ya)(VBATT)等于設(she)定(ding)電(dian)(dian)(dian)壓(ya)(ya)(ya)加上(shang)吸(xi)電(dian)(dian)(dian)流(liu)流(liu)經仿(fang)(fang)真(zhen)(zhen)電(dian)(dian)(dian)池(chi)(chi)內阻(zu)(0.100Ω電(dian)(dian)(dian)阻(zu))產生的(de)壓(ya)(ya)(ya)降(jiang)。仿(fang)(fang)真(zhen)(zhen)電(dian)(dian)(dian)路工作(zuo)(zuo)時(shi)(shi)的(de)電(dian)(dian)(dian)源(yuan)取(qu)自(zi)電(dian)(dian)(dian)池(chi)(chi)充(chong)電(dian)(dian)(dian)器(qi)(qi)輸出(chu)。

仿真電路的性能

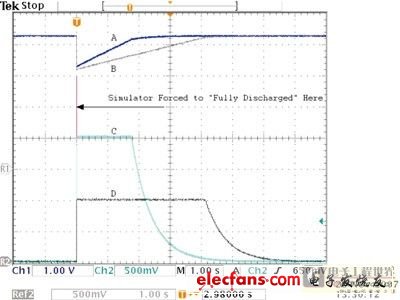

圖3為模擬鋰離子電(dian)(dian)池充電(dian)(dian)至4.2V時(shi)(shi)獲得(de)的(de)典型(xing)V-I波形。從圖中(zhong)可(ke)以(yi)看出(chu)兩個測試過程(cheng):一(yi)個是以(yi)1A初始快(kuai)充電(dian)(dian)流(liu)充電(dian)(dian)(曲(qu)線B和(he)D),另一(yi)個是以(yi)2A快(kuai)充電(dian)(dian)流(liu)充電(dian)(dian)(曲(qu)線A和(he)C)。這兩種情(qing)況下,首(shou)先進入(ru)CC階段充電(dian)(dian),直到(dao)電(dian)(dian)池電(dian)(dian)壓(ya)達(da)到(dao)終止(zhi)電(dian)(dian)壓(ya)4.2V。在此之后,電(dian)(dian)流(liu)呈指數衰減,而仿(fang)真(zhen)電(dian)(dian)池的(de)電(dian)(dian)壓(ya)保(bao)持不變。充電(dian)(dian)電(dian)(dian)流(liu)為2A時(shi)(shi)到(dao)達(da)終止(zhi)電(dian)(dian)壓(ya)所需的(de)時(shi)(shi)間更短,與預期(qi)設計相同。然而,請(qing)注意,電(dian)(dian)流(liu)加(jia)倍不會使充電(dian)(dian)時(shi)(shi)間減半(ban),只會使到(dao)達(da)CV模式的(de)時(shi)(shi)間減半(ban),與真(zhen)實電(dian)(dian)池負載的(de)測試情(qing)況一(yi)樣(yang)。

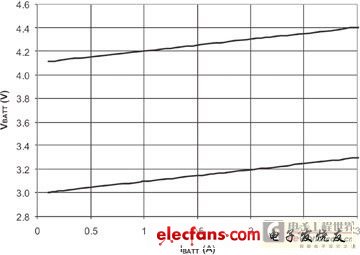

圖4為兩個不同(tong)設(she)置電壓(ya):3V和4.1V時的吸電流V-I曲(qu)線。兩個曲(qu)線的動態(tai)電阻(zu)(用斜率表(biao)示)僅僅是由0.100Ω電阻(zu)模擬的電池內阻(zu)。

圖3 根據圖2電池仿真電路繪制出的圖形,快速充電波形表明兩種條件下電池充電器的(de)工作情況,分別是:CC階段(duan)提供1A (曲(qu)線B和(he)D)和(he)2A (曲(qu)線A和(he)C)充電(dian)電(dian)流

圖4 圖2電(dian)(dian)路在(zai)電(dian)(dian)壓為4.1V (上部曲(qu)線)和3V (下部曲(qu)線)時的(de)吸入電(dian)(dian)流,兩種情況下斜率(lv)均代(dai)表0.1Ω內阻

由于鋰離子電池充電過程需要一小時或更長時間,利用實際負載測試鋰電池充電器將非常耗時,而且往往不切實際。為了加快電池充電器測試,本文介紹了一個簡單電路,用來模擬鋰離子電池。該電路提供了一個不使用實際電池對鋰電池充電器進行測試的有(you)效手段。